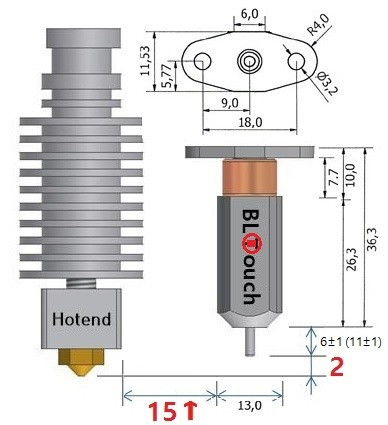

Bl touch dimension

Free returns are available for the shipping address you chose. You can return the item for any reason in new and unused condition: no shipping charges. Check the product details and customer reviews to learn bl touch dimension about this item. Carbonfree Certified determine the carbon footprint of the product, and associated carbon emissions are offset with reduction projects, bl touch dimension.

AUD BLTouch is an auto leveling sensor for 3D Printers that can precisely measure the tilt of Bed surface. It could work with any kinds of bed materials, such as glasses, woods, metals, and so on. Main functions and controls of BLTouch are the same as usual auto bed leveling sensor, consists of RC servo and micro switch. Thus, BLTouch can be applied on almost every board. BLTouch is fulfilled with simple structure and high precision by using progressively designed solenoid and hall sensor. BLTouch can be easily applied, since it has a small and simple structure.

Bl touch dimension

Main functions and controls of BLTouch are the same as usual auto bed leveling sensor, consists of RC servo andmicro switch. Thus, BLTouch can be applied on almost every board. BLTouch is fulfilled with simple structure and high precision by using progressively designed solenoid and hall sensor. But assembled with the low quality 3D printer, we just get the value as 0. It was the same BLTouch Actually, around 0. BLTouch can be easily applied, since it has a small and simple structure. On idle state, while the push-pin is whether pulled out or retracted, there are no any electric current flowing on solenoid. Standby electric current in the whole device is below average of 15mA on working state, but while the pin is moving, in a sudden about ms, under mA flows in the device. Low power consumption even drops joule heating, and it prevents heat problem. BLTouch is controlled by hall effect, providing high precision. Thus the bed material can be freely selected. BLTouch is a small, and technology-intensive device. Build size can be set larger than other existing auto bed leveling sensor.

Thus, BLTouch can be applied on almost every board. Control by G-code.

English Japanese Korean. BLTouch is a type of electronic component for 3D printer with built-in semiconductor Hall sensor or optical sensor. BLTouch is an auto leveling sensor for 3D Printers that can precisely measure the tilt of Bed surface. It could work with any kinds of bed materials, such as glasses, woods, metals, and so on. BLTouch is implemented with a simple structure and high precision by using an innovatively designed solenoid and detector Hall sensor or optical sensor. BLTouch vs.

Sign-up to our newsletter to receive the latest promotions, new products and sales. Directly to your inbox. Lost password? Recover password. Remembered your password? Back to login. Learn all you need to know about BLTouch auto bed leveling sensors: what they are, how they work, and setup guide instructions.

Bl touch dimension

I earn from qualifying purchases if you decide to make a purchase through these links — at no additional cost for you! Sensors for automatic print bed leveling significantly reduce the preparation time for FDM 3D printing. Many 3D printers can be upgraded with such sensors. The metallic sensor pin of the CR-Touch cannot collide with the print bed because it is always automatically retracted. Even though both sensors look pretty similar at first glance, there are more differences that will be highlighted in this article.

Pokemon black 2 action replay

Build size can be set larger than other existing auto bed leveling sensor. Overall, I am extremely pleased with the performance of the BL Touch and, having fixed my loose connection to the mainboard, the unit itself works perfectly every time. Firmware Setting e. Step 1: Copy the file below and overwrite at the Marlin folder. And then the BLTouch has been invented. Eligible for Return, Refund or Replacement within 30 days of receipt. Added to. Related Climate Pledge Friendly items. Its been a few weeks now and its just got to a point in confidence that I could hit start and walk away not recommended. Secure transaction Your transaction is secure. It could work with any kinds of bed materials, such as glasses, woods, metals, and so on. Push-pin Correct position of Core V3. G4 P ; delay for BLTouch.

First layer adhesion issues or the extruder skipping steps during the initial layers are common problems when working with 3D printers. They are often caused by improper bed leveling and can significantly affect the quality of your 3D prints and, consequently, your 3D printing experience.

Hall sensor cannot be used because of the strong magnetic field of the solenoid. Control by G-code Signal Timing Diagram. In 3d printing it is important to have level extremely well leveled otherwise the first layer would be layed properly and the prints would come off the bed. Next page. I took away a star due to poor documentation and difficult installation. Some mention that it is incredibly accurate, while others say that it was not calibrated, produces slightly less accurate meshes, and has horrible standard deviations. I am in heaven with my BLTouch, it is incredibly accurate , since I moved over to using it vs inductive sensors I've never had issues with first Marlin firmware Please update the firmware in the following order: Step 1: Copy the file below and overwrite at the Marlin folder. Therefore, BLTouch must be installed perpendicular to the ground. Add to Cart. Customers are dissatisfied with the length of the mechanical components. Sold by.

I think, that you are mistaken. Write to me in PM.

Your idea is brilliant