Bosch fuel injection pump calibration chart pdf

Forgot your password? When you click on links to various merchants on this site and make a purchase, this can result in this site earning a commission.

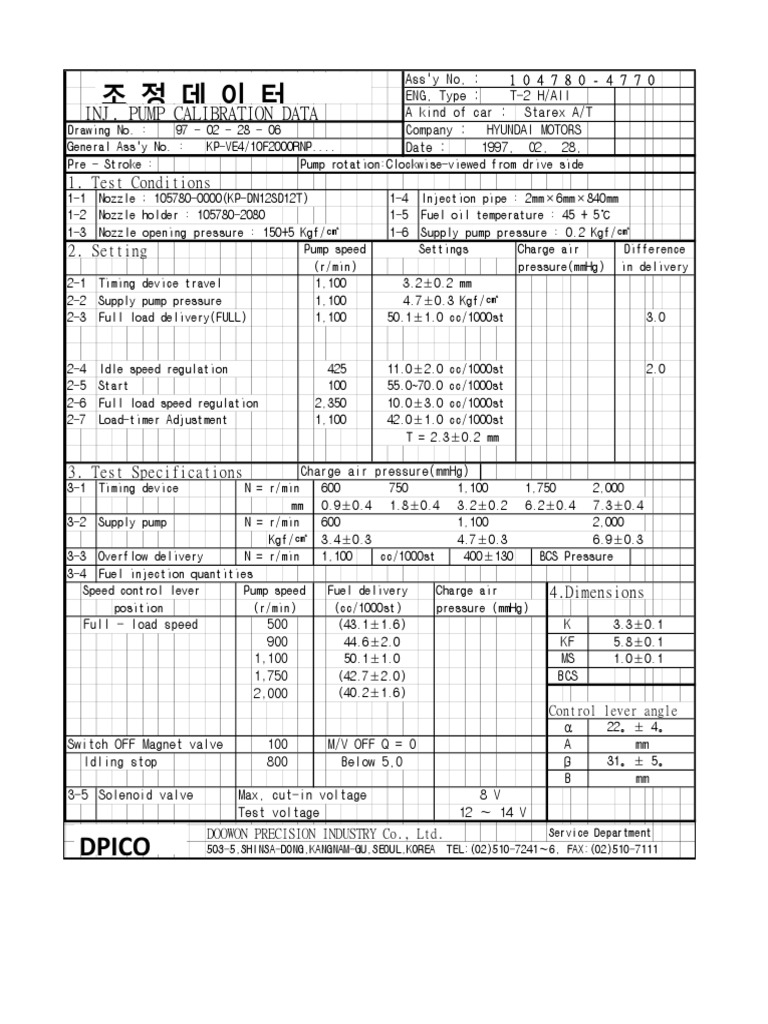

Then calibrate pump as per calibration chart. Loosen the lock nut of the governor shaft. Run the test bench at the specified speed as per 1. Keep the control lever in maximum position. Screw-out governor shaft slowly till the vane pump pressurebegins to fall. Lock the governor shaft by tightening the lock nut to the specified torque. Note: 3 X : Average of the cylinders 1.

Bosch fuel injection pump calibration chart pdf

By using our site, you agree to our collection of information through the use of cookies. To learn more, view our Privacy Policy. To browse Academia. For a diesel engine, fuel pressure time setting and calibration are very important parameters, which influence and increase the engine efficiency, performance, emissions, and combustion. Other injection parameters affecting engine performance are rate of injection, injection pattern, number of injections etc. A single cylinder research engine was used to experimentally determine the effects of fuel injection strategies and injection timings on engine combustion, performance and emission characteristics. The experiments were conducted at constant speed rpm with two FIPs and bars respectively and different start of injection SOI timings. Brake thermal efficiency BTE increased with increased injection pressures while exhaust gas temperature and brake mean effective pressure BMEP increased up to bars. These parameters reduced slightly with increase in fuel pressure time pump. Diesel engine combustion quality is based on the formation of fuel-air mixture. Enormous efforts have made to reduce the harmful diesel engine emissions.

Almost anything that significantly affects combustion efficiency besides an actual rich mixture will result in excess oxygen in the exhaust stream. The performance and emission characteristics of diesel engines depend on many parameters.

.

FORWARD This manual is part of a series of manuals intended to assist service technicians in maintaining International Engines in accordance with the latest technical advancements. Due to a commitment of continuous research and development some procedures, specifications and parts may be altered to improve International products and introduce technological advances. Periodic revisions may be made to this publication and mailed automatically to "Revision Service" subscribers. The following literature supporting the Series Diesel Engine is available from:. This manual is arranged in sections with the pages numbered consecutively in each section.

Bosch fuel injection pump calibration chart pdf

.

Vanity mirror near me

A single cylinder diesel engine was tailored to operate in dual fuel mode. Let's see Test Specifications Test Specifications. The 'cone' is metering based on 2 factors- revs and where the throttle is. Check out the digital resources listed below. Jump to Page. Reyadh Almehaideb. This eliminates the need for high-pressure fuel lines running from the fuel pump to each injector. Nozzle effects on the injection characteristics of diesel and gasoline blends on a common rail system. The diesel engine power performance values such as indicated pressure, indicated horse power, shaft horse power, brake horse power, break mean effective pressure and fuel consumption investigated both of variation engine speeds-fixed load and fixed engine speed-variation loads by the fuel injection pressure variation. To validate the model, a comparison is made between simulation data and experimental data including torque and power showing the validation error is less than 6.

.

Harga Terjangkau! Jump to Page. LPG can replace petrol and also it reduces NOx, soot and particulate matter. Precise control over the fuel injection process is one of the most important factors and plays a very important role in combustion to increase the engine performance with minimal exhaust emission. Energy, This should be rated RPM or higher. Two running things. The fuel injection pressure is one of the important operating parameters which affect atomization of fuel and mixture formation and hence it determines the performance and emissions of a diesel engine. On site after that i have started engine and checked all the parameters found ok, as per standard values of given engine application and its working accurately,there is no any fuel leakages,no white smoke and no engine hunting issues. Jason Anthony. Calibration Diesel engines Setting Time. This condition results in more power without sacrificing engine durability. Along with alternate fuel, engine performance and emissions are also affected by various engine operating parameters. In addition, both, cylinder gas temperature and pressure were found to be clearly affected too.

Rather amusing answer