Buna n is a polymer of

Additional Information. Last updated on Feb 28,

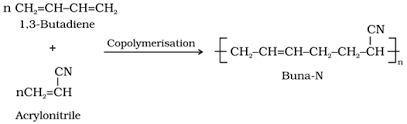

Buna- N synthetic rubber is a copolymer if:. Buna-N synthetic rubber is a copolymer of:. Buna - N synthetic rubber is a copolymer of. Buna -N synthetic rubber is a copolymer of :. Buna- N synthetic rubber is a copolymer of:.

Buna n is a polymer of

Nitrile rubber , also known as nitrile butadiene rubber , NBR , Buna-N , and acrylonitrile butadiene rubber , is a synthetic rubber derived from acrylonitrile ACN and butadiene. This rubber is unusual in being resistant to oil, fuel, and other chemicals. NBR is used in the automotive and aeronautical industry to make fuel and oil handling hoses , seals, grommets, and self-sealing fuel tanks. It is also used in the nuclear industry to make protective gloves. Nitrile butadiene is also used to produce moulded goods, footwear, adhesives, sealants, sponges, expanded foams, and floor mats. Its resilience makes NBR a useful material for disposable lab, cleaning, and examination gloves. Nitrile rubber is more resistant than natural rubber to oils and acids , and has superior strength, but has inferior flexibility. The first commercial production began in Germany in The raw materials came from the Polish coalfields. Emulsifier soap , acrylonitrile, butadiene , radical generating activators, and a catalyst are added to polymerization vessels in the production of hot NBR. Water serves as the reaction medium within the vessel. Because several monomers capable of propagating the reaction are involved in the production of nitrile rubber the composition of each polymer can vary depending on the concentrations of each monomer added to the polymerization tank and the conditions within the tank.

Bihar Vidhan Parishad Security Guard.

Acrylonitrile Butadiene Rubber NBR or Nitrile rubber is one of the most popular compounds for automotive applications. It also is well known as Buna-N. This name came from one of the first base polymers patented in , therefore people commonly use this name for all classes for Nitrile to this day. The amount of Acrylonitrile is varied to provide different range of oil resistance the base polymer will have. Typical ranges are between 14 to 50 percent acrylonitrile.

Acrylonitrile Butadiene Rubber NBR or Nitrile rubber is one of the most popular compounds for automotive applications. It also is well known as Buna-N. This name came from one of the first base polymers patented in , therefore people commonly use this name for all classes for Nitrile to this day. The amount of Acrylonitrile is varied to provide different range of oil resistance the base polymer will have. Typical ranges are between 14 to 50 percent acrylonitrile. As the Acrylonitrile increase the polymer will have greater oil and fuel resistance.

Buna n is a polymer of

Nitrile rubber is a synthetic rubber copolymer of acrylonitrile ACN and butadiene that you may know better under trade names like Nipol, Krynac and Europrene N. Why might you consider specifying nitrile for your application? This is partly because it displays excellent resistance to petroleum-based oils, fuels, water, alcohols, silicone greases, hydraulic fluids. However, it also has a good balance of desirable working properties like low compression set, high abrasion resistance and high tensile strength. Nitrile is a family of unsaturated copolymers of 2-propenenitrile and butadiene monomers 1,2-butadiene and 1,3-butadiene.

Keyboard ghosting microsoft test

SSC Selection Post. Leaving Soon? Goa Police Constable. An object is placed between two inclined mirrors. Chhattisgarh AE. Stearic Acid. MP Vyapam Group 4. Maharashtra Prison Department Clerk. Indian Coast Guard Assistant Commandant. Maharashtra Agriculture Assistant.

Nitrile rubber , also known as nitrile butadiene rubber , NBR , Buna-N , and acrylonitrile butadiene rubber , is a synthetic rubber derived from acrylonitrile ACN and butadiene. This rubber is unusual in being resistant to oil, fuel, and other chemicals. NBR is used in the automotive and aeronautical industry to make fuel and oil handling hoses , seals, grommets, and self-sealing fuel tanks.

The amount of Acrylonitrile is varied to provide different range of oil resistance the base polymer will have. Which of the following polymer is formed by condensation polymerisation mechanism? HP SET. Karnataka SDA. These polymers will give improved tensile strength, tear, modulus and abrasion resistance. Antioxidant are needed in NBR compound to prevent degradation of the unsaturated polymer backbone caused by high temperatures. SSC Selection Post. CG TET. NVS Catering Assistant. MBA Entrance Exam. Graphite or moly disulfide can be added as a lubricant to compounds, just assure your application can handle particulate coming off the compound.

In my opinion you are not right. I am assured. Write to me in PM.

Excuse for that I interfere � At me a similar situation. Write here or in PM.