Cpk interior products

CpK moulding, assembly and sequencing experts can add significant value to your next automotive interior. We excel at collaborating, coordinating, innovating and delivering flawless results. True quality begins with impeccable materials.

Research and product development was performed in collaboration with Western University. Located in Ontario, CpK manufactures auto parts such as dashboards, consoles, and produces their own plastic resins in their compounding facility in Corbyville, a rural area of Belleville. The new product will make vehicle interiors safer for multi-person use - great news for carpooling and ride sharing! In the future, germs and viruses will not be able to survive on the plastic surfaces inside vehicles. Imagine all the possibilities for products that use plastic!

Cpk interior products

.

The CpK advantage starts with our proprietary compounding of performance materials, where process innovation blends with plastics engineering to deliver unsurpassed efficiency and optimum performance in every automotive part we create, cpk interior products. In the future, germs and viruses will not be able to survive on the plastic surfaces inside vehicles.

.

The core of research and development at CpK starts with our team of dedicated scientists and engineers. CpK is at the forefront of the materials evolution and is incorporating new materials to produce products with unique advantages. Experience combined with a statistical approach to the manufacturing process deliver perfect results, every time. Choose CpK IP for quality. Weight reduction innovation is achieved by utilizing a compressed sustainable natural fiber that is back injected with a thermoplastic that provides additional structure. Low cycle times and high fiber content allows CpK to design advanced composites with industry leading properties.

Cpk interior products

CpK moulding, assembly and sequencing experts can add significant value to your next automotive interior. We excel at collaborating, coordinating, innovating and delivering flawless results. True quality begins with impeccable materials. CpK employees are energized to deliver results for our customers. It is our mission that leads us to achieve heightened levels of performance in process, accuracy and customer service. CpK moulding, assembly and sequencing experts can add significant value to your next interior.

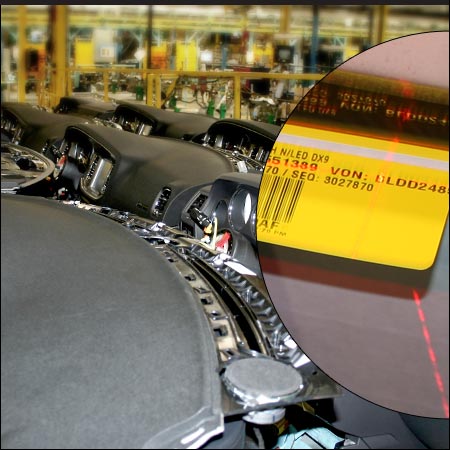

Ts escort uk

Vertical integration is a mainstay at CpK and in-house injection moulding of Class A interior products, structural components and large complex modules is a core competency. Precise assembly depends on exacting attention to every detail, especially with hundreds of module variations passing through a single assembly operation. A Team Of Professionals. Our Little Story Precision is Everything. Efficient Design. Cast Skin and Foam At CpK, cast skin and foam products provide a premium look and exceptionally soft feel. Search form Search. Exquisite Interiors World class manufacturing combined with only the best materials produces the most amazing automotive interiors. Latest News. Sequencing At CpK, we have sequencing down to an art form. True quality begins with impeccable materials. At CpK we strive to be the leading interior automotive supplier in North America. Our fine-tuned capabilities allow infinite combinations to meet the unique specifications of the Original Equipment Manufacturers and Tier One automotive interior suppliers, seamlessly and successfully.

Home page.

Design For Manufacturing CpK moulding, assembly and sequencing experts can add significant value to your next interior. Injection Moulding Vertical integration is a mainstay at CpK and in-house injection moulding of Class A interior products, structural components and large complex modules is a core competency. The new product will make vehicle interiors safer for multi-person use - great news for carpooling and ride sharing! In the future, germs and viruses will not be able to survive on the plastic surfaces inside vehicles. Sequencing At CpK, we have sequencing down to an art form. The CpK advantage starts with our proprietary compounding of performance materials, where process innovation blends with plastics engineering to deliver unsurpassed efficiency and optimum performance in every automotive part we create. True quality begins with impeccable materials. At CpK, we have sequencing down to an art form. At CpK, precision runs much deeper than the detailed surface of our cast skin automotive interior products. This anti-viral additive could eventually be used in many other applications. Performance Starts Here. Providing expertise at every phase of our world-class automotive parts manufacturing process, and with the deepest bench of manufacturing and product experts in the industry, we deliver award winning craftsmanship synchronized with your vehicle goals. We will get back to you within 1 business day. Research and product development was performed in collaboration with Western University. Shape the future with our proficiency in mould tuning and design plus always receive the latest technology in graining, material haptics and colour.

This version has become outdated