Cummins top stop injector adjustment

Log in. Sign up.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums! Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Forums Bookmarks New posts Search forums. What's new New posts New profile posts Latest activity. Members Current visitors New profile posts Search profile posts.

Cummins top stop injector adjustment

Log in. Sign up. Home Forums Farming Community Tractors. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Can you use either one? Mine is a big cam 1. It appears that there are several different injectors that are used by Cummins How do you verify which you have I have adjusted valves for years but there methods seem a little vague I don't want to have to do it 5 times to get it right and I do not want to break anything. Cummins was not very helpful because they are not computerized controls most of the older guys that did the old stuff arn't around anymore. Sort by Oldest first Oldest first Newest first Most reactions. I don't want to bend or break anything, and I am not saying you would have me do anything to damage anything, I am just trying to understand the process through the mechanics of how it is done. The inner base methods either using a dial indicator for std injectors or the inch pound setting for top stops doesn't ensure the injector is seated when at top dead center. Keep in mind just because the data tag shows an injector trave spec ex.

Big Horn 21 Replies. I've Disabled AdBlock. The crossheads are exposed here to illustrate that one rocker lever operates two intake or two exhaust valves with equal tension.

We'll discuss the theory and procedures for setting injector plunger travel using the dial indicator method D. Included is the recommended procedure for checking and adjusting crossheads. We'll discuss the effects of crosshead adjustment related to valve operation. This is a Top Stop adjustment fixture It's required to set Top Stop plunger travel, and to torque the splined locknut to 55 ft. The plunger travel is set by preloading the injector spring with the weighted handle at a prescribed travel.

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Sort by Oldest first Oldest first Newest first Most reactions. Your manual will no doubt show you this, but one dial registers via a long stem through a removed injector hole the piston position relative to crankshaft rotation, while another registers the push rod travel.

Cummins top stop injector adjustment

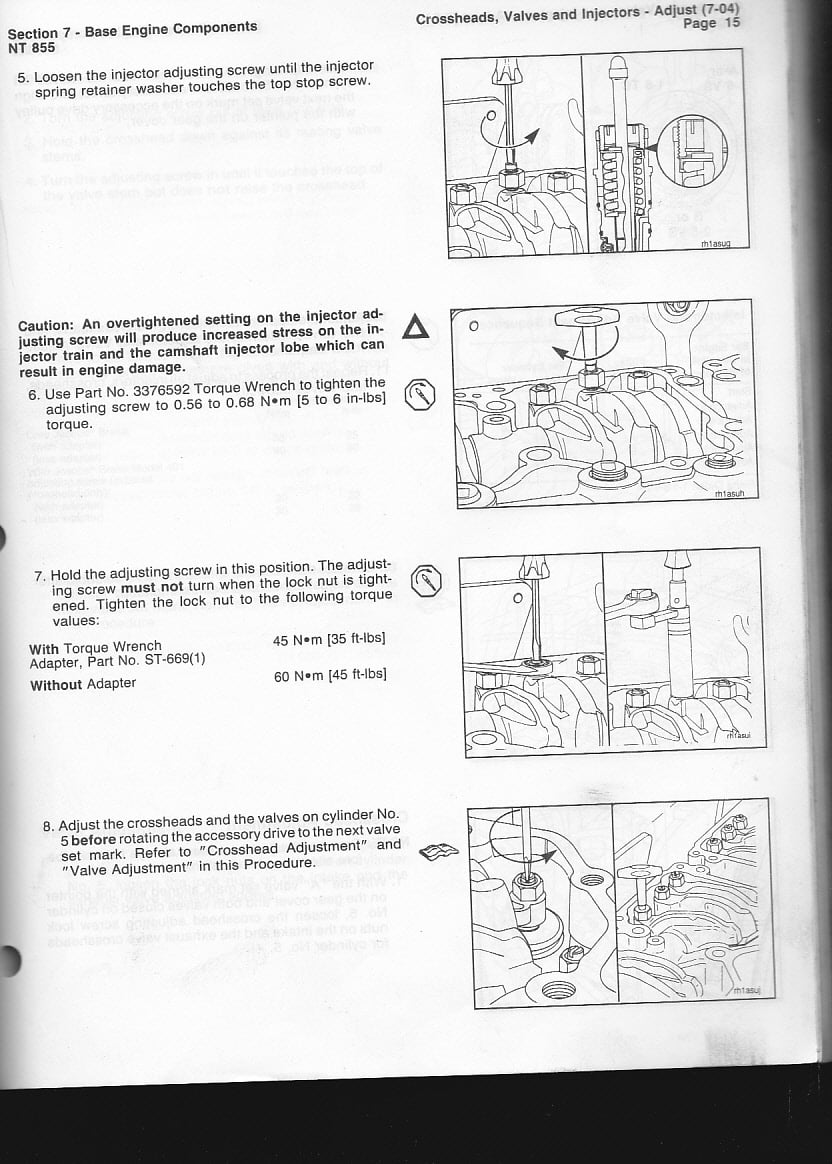

This post is mainly written to introduce how to adjust crosshead, injector and valves of Cummins NT diesel engines correctly. Pay attention to reading and you will learn more. Crosshead Adjustment. Note: Crosshead adjustment should always be made before attempting to adjust the valves. Loosen the locknut on the crosshead adjusting screw. Turn the adjusting screw out at least one turn. Hold the crosshead down against its mating valve stem.

Meme feliz cumpleaños

Home Forums Farming Community Tractors. Hold the crosshead in place and lightly turn down the adjusting screw until you feel contact. Don't ever try setting top stop injectors using the travel method. At this position both the jntake and exhaust valves are closed, providihg lash in the valve train to ensu re correct clearance settings. What's new New posts New profile posts Latest activity. When you think about it this way, you are taking any wear on the cam out of the equation because the push rod assembly is sitting on the high lobe of the cam giving you the actual lift you will see once the engine is running. Open navigation menu. Note the position of the screw slot. The injector and valve camshaft lobes have definite surface positions. Advance the screw slightly and lock it down. When preloading Top Stop injectors, use the D. Install the app. We have thoroughly discussed the theories and procedures for adjusting the PT type D Top Stop and non Top Stop injectors, as well as the crossheads and valves. Good luck, Lorne. If you want to see a real turbo set up, talk to your local old timmer at Cummins about the Hyper-Bar KV

Package Dimensions: W7.

MVT models use a special camshaft design. Log in. To do this, back out the injector adjusting screw until you feel the spring washer contact the stop nut. JavaScript is disabled. Securely tighten the hold down into place in the rocker box housing. It has been said that the TM has an error as well. When the accessory drive is positioned at the "A" mark, cylinders 1 and 6 have traveled on their downward stroke. I njection Ramp. The injector roller has just passed B. Recommended Communities. Jump to Page.

I do not understand something