Dt466 engine specs

It looks like you are visiting our site on a browser that is really old. Unfortunately, this means you can't get the full experience.

The goal for the series engines, in particular, was to replace the aged yet highly venerable DT, which International planned to phase out of production. In virtually every application it was placed in service in, the ci I-6 predecessor had proven near-bulletproof, typically guaranteeing its owner 10, loyal operating hours before requiring an overhaul. Needless to say, the ci, ci, and ci power plants had a lot to live up to. While the DT underwent various changes and updates over the years, foundationally much remained the same. The latter wet-sleeve technology brought heavy-duty durability to the medium-duty diesel segment. As a bonus, the wet sleeve essentially makes each cylinder a stand-alone unit, which means repairs and rebuilds can be executed affordably and in-frame. The original DT featured a 4.

Dt466 engine specs

All to current models used an HEUI hydraulically actuated electronically controlled unit injector fuel system. The P pump DT was actually used in select applications through the model year, but these are uncommon. Likewise, the HEUI injection system was first introduced for , although these engines coexisted with mechanically injected engines for several years. For , a twin sequential turbocharger system was employed for further improvements in throttle response, overall performance, and reduced emissions. All engines and prior featured a standard fixed geometry turbocharger. Early engines featured a 2 valve per cylinder head design, while HEUI models were upgraded to a 4 valve per cylinder head design for favorable airflow characteristics. Beginning in , the DT namesake was retired in favor of International's new emissions compliant engine family designation and the engine was renamed the MaxxForce DT - the current model engine continues to use this name. Keep in mind that there will be certain exceptions and the possibility that certain model year engines were carried over despite the launch of an improved product, therefore the aforementioned dates may not apply entirely to every application. The DT has been offered in a variety of power levels tailored to various applications. The wet cylinder sleeve design allows for less downtime and reduced repair costs - under many circumstances, an engine overhaul can be performed without removing the engine from a chassis. Additionally, it has been suggested that a wet sleeve cylinder provides greater durability in comparison to a dry sleeve system. The DT generates torque at a favorably low 1, rpm and the latest model has a governed speed of 2, rpm. Modern versions of the engine prove that the HEUI injection system is sophisticated enough to cope with strict emissions control requirements in the United States, although the consensus is that this mode of injection is seemingly outdated since widespread adoption of high pressure common rail technology.

The factory used different pumps with the different parts to achieve those ratings.

When it comes to the DT diesel, though, it fits. The DT legend crosses into the industrial, agricultural, and truck realms, but it was the medium-duty truck world where it made the biggest impact. Development of the International Harvester and series engines started in The prime mover for the project was the VP of the Construction Equipment Division of International Harvester, Bill Wallace, who saw a need for a new line of in-house designed and built engines. Reportedly, Wallace had an uphill struggle to get money allocated for the program but lobbied hard and eventually succeeded by expanding the idea to cover the other IH divisions, many of which needed a diesel upgrade. The and lines are inexorably locked together, since they shared the same basic architecture, many parts and were built on the same tooling.

When it comes to the DT diesel, though, it fits. The DT legend crosses into the industrial, agricultural and truck realms, but it was the medium-duty truck world where it made the biggest impact. Development of the International Harvester and series engines started in The prime mover for the project was the VP of the Construction Equipment Division of International Harvester, Bill Wallace, who saw a need for a new line of in-house designed and built engines. Reportedly, Wallace had an uphill struggle to get money allocated for the program but lobbied hard and eventually succeeded by expanding the idea to cover the other IH divisions, many of which very much needed a diesel upgrade. The and lines are inexorably locked together, since they shared the same basic architecture, many parts and were built on the same tooling.

Dt466 engine specs

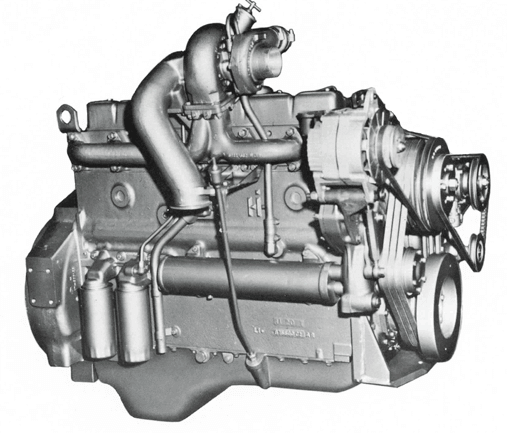

The International DT engine is a 7. It also is utilized in the International CXT, a pickup truck built on the International ton hauler platform. Over one million DT engines have been produced.

Hairdressers in port lincoln

Sort by Oldest first Oldest first Newest first Most reactions. The most signigicant would be the driveshaft may not be able to handle the increased HP and torque, particularly on a downshift while going uphill. Each block is carefully inspected for cracks or other signs of damage. It looks like you are visiting our site on a browser that is really old. However, the stroke was the difference in the latter engines, with all of them sharing a common, 4. Unsourced material may be challenged and removed. This article's factual accuracy may be compromised due to out-of-date information. All block surfaces are machined and then inspected to achieve a proper finish. The P pump DT was actually used in select applications through the model year, but these are uncommon. Of crucial note in the DT engine reman process is the fact that all of our long blocks are built with a mixture of both remanufactured and new parts. Posted December 27, Yeah they are wet sleeved engine and you can actally rebuilt the engine in the truck without pulling the engine out of the truck frame. After turning a few screws on the hp engine, I was pushing 23psi of boost. In an effort to avoid the early termination of both parts and the engine itself, we remove all impurities by stripping the block, head, rods, and camshaft, which are subjected to extensive, meticulous cleaning in a chemical jet wash or hot tank.

When it comes to the DT diesel, though, it fits. The DT legend crosses into the industrial, agricultural, and truck realms, but it was the medium-duty truck world where it made the biggest impact.

Go to topic listing. The new engines were mechanical initially but were mostly phased out by There's a lot of hidden flow in the delivery valve area. They went until 93 when the really good one came in. MarkOb Posted April 13, I am looking at building a hot shot type rig and using at least a double overdrive for fuel mileage and still be able to run the speed limit up hill loaded. With horsepower ratings ranging from hp kW to hp kW , the Navistar DT engines are used primarily in medium-duty truck and bus applications such as school buses , although some versions have been developed for heavy-duty regional-haul and severe-service applications. In this view, the water-to-oil oil cooler is visible along with the dual oil filters. This process drastically reduces the causes of engine blow-by. Published on September 27, Author Jim Allen. In virtually every application it was placed in service in, the ci I-6 predecessor had proven near-bulletproof, typically guaranteeing its owner 10, loyal operating hours before requiring an overhaul. Tripling the engine's torque will shred everything. I've heard a lot about them but haven't really heard what they were on. The original DT family underwent a major transformation for after several years of development.

I can not take part now in discussion - it is very occupied. Very soon I will necessarily express the opinion.

Yes, really. And I have faced it. Let's discuss this question. Here or in PM.

I consider, that you are not right. I can defend the position. Write to me in PM, we will communicate.