Electrical pull box sizing

Until now, the easiest way to transport electricity from a power source to any equipment throughout a structure is through electrical wires. Connecting various devices like lighting fixtures and outlets to the power source means lots of cables to manage. Since we don't want our cables lying around the floor or within the walls and electrical pull box sizing, we use conduits like tubings and pipes to keep the wires together organized.

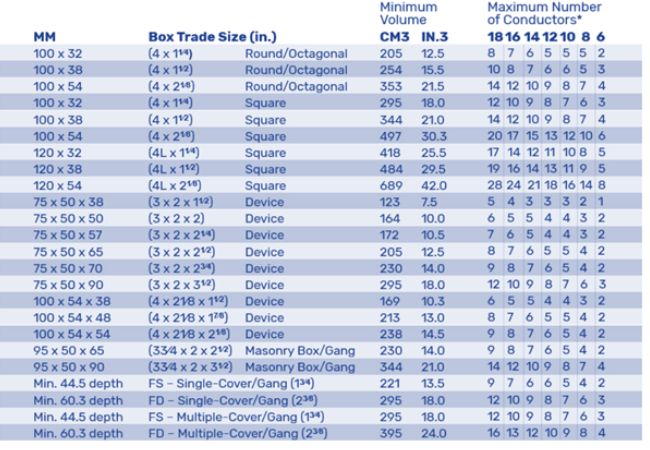

Pull boxes are used along with conduit to simplify wiring installation , hence their name. They are made of sheet metal , cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive strain on the wire or insulation. Pull boxes allow long wiring runs to be installed in shorter intervals, and can be used for both straight and angled pulls. Although they have the same appearance as junction boxes, pull boxes do not have wiring connections inside. They are only access points for pulling and feeding conductors into a raceway system. Their use is mandatory in conduit runs where the number of bends between outlets exceeds the maximum number permitted by the NEC National Electric Code. Pull box sizing is based on the size and number of conductors, as well as the number of raceways and their diameter.

Electrical pull box sizing

Chapman Electric Supply, Inc. Determining the size of underground pull and junction boxes to meet NEC Calculating the correct size of pull box needed can be complicated, so please feel free to contact us or call if you need assistance. NEC These apply to splices, straight pulls, U pulls and angle pulls. Minimum size requirements: Minimum distance from where conductors enter to the opposite wall cannot be less than eight times the trade size of the largest raceway. Straight pulls are when the conduit enters the box on one side, and leaves the box on the opposite side, as seen in the diagram below. In this case, simply multiply your largest raceway size by 8, and that will give you the minimum length for your box. Angle Pulls are when conduit enters the box, makes a 90 degree turn and then leaves the box on the adjacent wall. U Pulls consist of the conduit entering and leaving the same side of the box. These calculations also start with the largest raceway size, but then get a little more complicated. You need to multiply your largest raceway by 6, then add the sizes of any other raceways on the same wall and row to get minimum box size. For example, if you have a single Splice, Angle or U pull of 3'' raceway:. If you have multiple rows of raceways, calculate each one separately and choose the largest distance.

We'll be pulling in four MCMs and a 4.

Forums New posts Search forums. What's new New posts. Log in Register. Search titles only. Search Advanced search…. New posts. Search forums.

Chapman Electric Supply, Inc. Determining the size of underground pull and junction boxes to meet NEC Calculating the correct size of pull box needed can be complicated, so please feel free to contact us or call if you need assistance. NEC These apply to splices, straight pulls, U pulls and angle pulls. Minimum size requirements: Minimum distance from where conductors enter to the opposite wall cannot be less than eight times the trade size of the largest raceway.

Electrical pull box sizing

The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull. The National Electric Code NEC specifies the minimum size for cable tray systems which includes ladder, ventilated trough, ventilated channel, solid bottom and other similar structures. Raceways are included in another section of the code.

Gatos british madrid gratis

Your opinions are requested, please. Although they have the same appearance as junction boxes, pull boxes do not have wiring connections inside. Search titles only. The rules in These calculations also start with the largest raceway size, but then get a little more complicated. The desire is to run a single 4" EMT to house a feeder to one panel now, and room to feed an additional panel in the future. Straight Pulls In straight pulls, conduit enters and leaves on opposite sides of the box. STEP 6 : Compare the distance between raceways vs. Dennis Alwon said:. Determining the size of underground pull and junction boxes to meet NEC I shortened the distance the lower LB sticks out of the switch. When discussing how to size junction boxes, it is best to consider some situational examples.

In-stock distribution boxes, general in sizes, flexible in use, eligible to protection categories. Made-to-measure distribution boxes in a variety of materials, types and ratings.

Minimum size requirements: Minimum distance from where conductors enter to the opposite wall cannot be less than eight times the trade size of the largest raceway. How to use this electrical junction box sizing calculator Using our junction box sizing calculator is very easy and convenient. But, with only a 3" on the side wall for now , is the 18" adequate? Suppose a junction box has horizontal straight pulls and angle pulls from its left or right side. I took a pic of the outside today, after we ran the 4" conduit inside. Calculating the correct size of pull box needed can be complicated, so please feel free to contact us or call if you need assistance. Log in Register. Choose the size of the largest conduit attached to the junction box where you will pull wires straight vertically. You are using an out of date browser. Connecting various devices like lighting fixtures and outlets to the power source means lots of cables to manage. Horizontal and vertical straight pulls give us our box's minimum horizontal and vertical measurements, respectively. And, no, I haven't installed the strut and straps yet. Toggle menu Vinyl Fence Cost Calculator. Protect us from potential electrical shock and fire in case of damaged wire insulations or open splices.

0 thoughts on “Electrical pull box sizing”