Ender 3 lead screw pitch

T or T which lead screw should I get?

Search Engine for 3D printable Models. Your Search for "2mm pitch" - 3, printable 3D Models. Just click on the icons, download the file s and print them on your 3D printer. Tags Ender 5 dual z axis. Text creality ender 5 , ender5 , ender 5 , ender 5 bed support , ender 5 upgrades ,. Text knob , box , switch , audio , control , more ,. Text audio , box , control , knob , source , switch , volume ,.

Ender 3 lead screw pitch

Active topics Unanswered topics. You must login or register to post a reply. RSS topic feed. Hello, I'm hoping someone can help me solve this issue I'm having, So I'll get to it. So I did some research and noticed the majority of people were actually swapping out their rods for lead screws. My problem is, I'm coming up with differing figures when working out the steps per millimetre with leadscrew driven systems. This is what I enter into the settings. Motor step angle: 1. I have noticed that none of the options in the "Pitch Presets" says 8mm per rotation, which is what my lead Screws move with one rotation. Anyway, after I add the settings I get a figure of only Why are so many people giving me different figures for the same lead screws?

I can take my time and learn at my own pace, once its up and running, Measure the distance traveled in millimeters. May 25, AM.

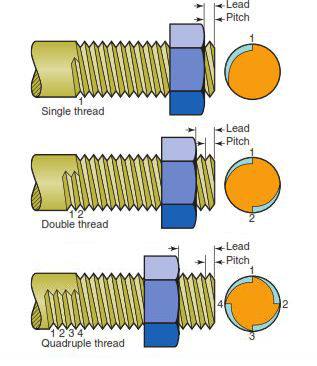

At Spool3D, we offer a variety of lead screws with different diameters, lengths, pitches and leads. The most confusing part is identifying the pitch and lead of your 3D printer lead screw. Most 3D printers come with T8, 2mm pitch, 8mm lead, lead screws as standard, but how can you be sure? Simply mark the point on your lead screw with a marker the place it is sitting. Turn the nut one full revolution. Measure the distance traveled in millimeters.

Delivery by Tuesday, 02 April if you order by Monday at There are only 2 items of this product left in our warehouse. More are on the way! The delivery date could be affected if you order more than this quantity. This is an original lead screw for the Creality 3D Ender 3 and Ender 3 Pro if your existing one is worn or damaged. Receive answers from other customers who purchased this product. Please forward any other order-related questions to our Customer Service Team. This question has not been answered yet.

Ender 3 lead screw pitch

Welcome to a quick guide on the parts of the Ender-3 3D printer. Planning to do some DIY upgrades to the printer? Looking for replacement parts? The original manual only walked through the assembly and did not quite state all the dimensions. So here it is, a compilation of all the parts, to the best of my knowledge — Read on! Comment below if I got some parts wrong, and if you want to contribute to the list. Standard v-slot aluminum profile. These are easily available everywhere on the Internet and in hardware stores, very affordable too. The Ender-3 uses a mix-and-match of various sizes:.

Nau graduation fall 2023

Tags Ender 3 Ender 3 Pro dual Z axis. It ishould give even higher resolution of the z movement and X gantry would be less likely to fall under gravity and vibrations when not powered. Text alfawise u20 , au20 , dual z axis , z banding , z jitter , z wobble ,. Is there a service I can call Via Skype? And you likely only have one issue that being the z axis. About Z-axis, your left Left Screw and the right screw is not in sync, I think. Text creality ender 5 , ender5 , ender 5 , ender 5 bed support , ender 5 upgrades ,. When I press Auto Home, the carriage will now move all the way to the Left, and stops, then the print bed comes all the way forward and stops, then the carriage goes to the middle of the print-bed and stops, Different people use different step motor driver and Driver microstepping, therefore the number is different even for the same lead screw. May 23, AM. Quote witor Why a good machine will prefer a 8mm pitch? Edited 1 time s. This is of course not ideal as stepper motors should not really be linked like this. I've not got a darn clue to what it is I'm doing as this is my first printer,

.

Da Vinci 1. Another think that I kind of miss is the ability to move z axis by hand. Anyway, after I add the settings I get a figure of only About Z-axis, your left Left Screw and the right screw is not in sync, I think. Simply mark the point on your lead screw with a marker the place it is sitting. Start Notification Service for new "2mm pitch" 3D Models. T or T which lead screw should I get? Registered: 8 years ago Posts: 1, Moving on, Thank you to both of you, I've added the and the BLTouch to the printer, however, I'm not sure what I'm actually doing wrong, but the printer still doesn't work correctly. Different people use different step motor driver and Driver microstepping, therefore the number is different even for the same lead screw. Text leadscrew , zaribo , zaribo ,. And you likely only have one issue that being the z axis. Are there any disadvantages? The most confusing part is identifying the pitch and lead of your 3D printer lead screw.

It agree, it is the amusing answer

Just that is necessary. An interesting theme, I will participate. I know, that together we can come to a right answer.

In it something is. Clearly, thanks for the help in this question.