Faceting machine

Skip to content.

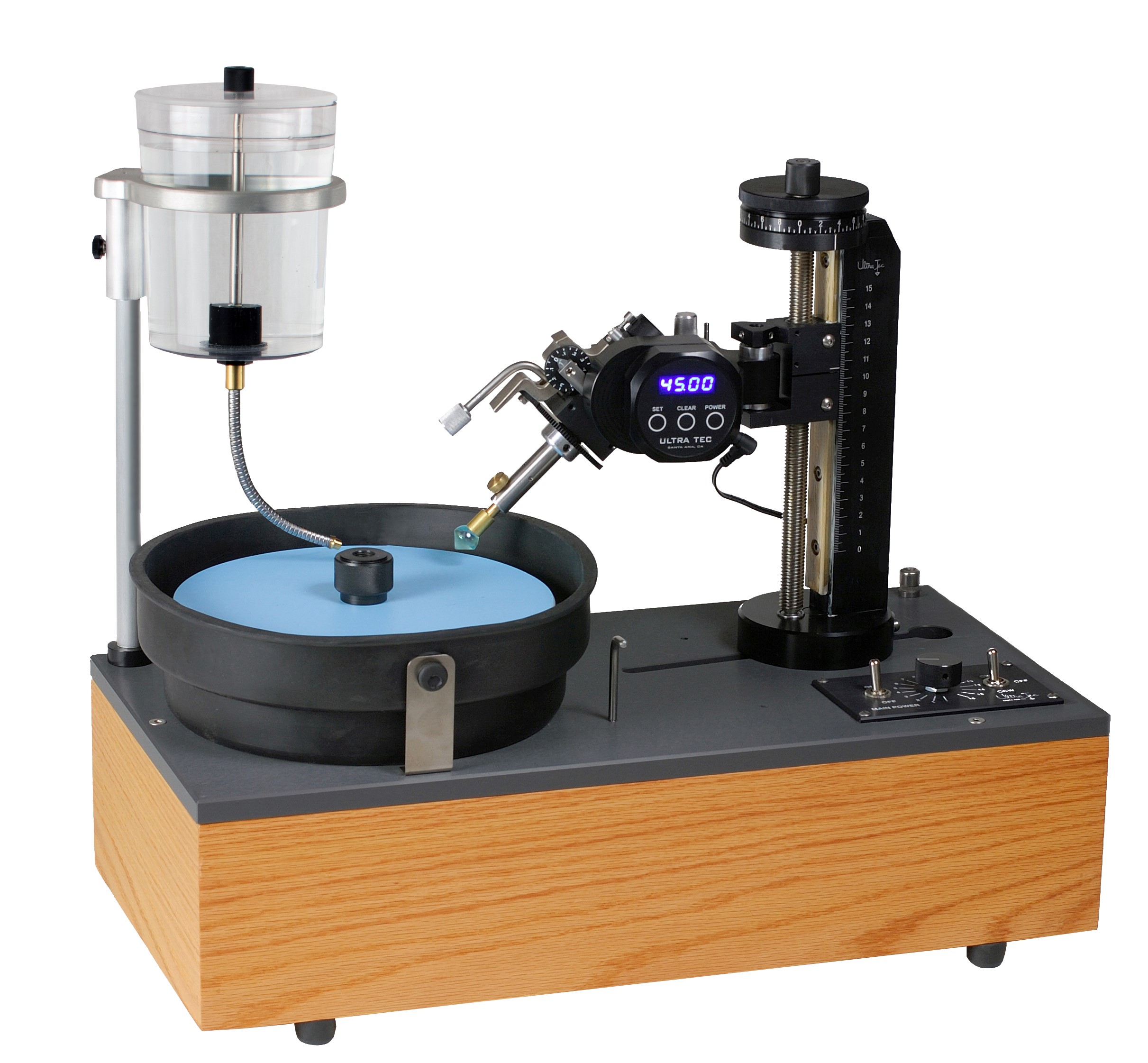

A faceting machine is broadly defined as any device that allows the user to place and polish facets onto a mineral specimen. Machines can range in sophistication from primitive jamb-peg machines to highly refined, and highly expensive, commercially available machines. A major division among machines is found between those that facet diamonds and those that do not. Specialized equipment is required for diamond faceting , and faceting as an occupation rarely bridges the gap between diamond and non-diamond workmanship. The vast majority of jewelry -store gemstones are faceted either abroad in factories or entirely by machines. Diamonds are the exception, owing to the training and specialized equipment required to facet them.

Faceting machine

.

Index Wheel : If you view a gemstone from the top, you will see it has some type of symmetry. The vast majority of jewelry -store gemstones are faceted either abroad in factories or entirely by machines, faceting machine. Height Adjustment : The depth of a facet is determined faceting machine how high or low the head assembly is relative to the lap.

.

The GemMaster. These features are designed to make the machine the easiest and most accurate faceting machine available while slashing the required time. As the first facet in a series is cut to the desired angle and depth, the needle moves up the meter scale. When the facet is completed and the grinding stops, the position of the needle on the meter is noted. As each subsequent facet in a series is cut, an audible tone denotes the identical needle position on the meter. Upon hearing this tone, you know to move on to the next facet. When using this method, upon completion not only are all your facets identical but your time involved is cut dramatically! If the use of the tone is not desired, a switch is provided to turn it off and allow only the meter needle to operate.

Faceting machine

The Facetron. All faceters know that the precision of their facets is directly linked to the precision of the index gear. The Facetron comes equipped with the 96 index gear, but you can choose the index gear you want. After you dial in the desired angle on the digital protractor of the Facetron, the Dial Indicator Stop System shows you the exact stopping point. The dial indicator stop system consists of a new hard stop and dial indicator for dependable and accurate depth of cuts.

T20 world cup 2021 semi final rules

This container has an exit tube that drains into a second receptacle. The drip tank allows the user to choose a drip rate via spigot and to position the spigot over the lap, nearer or farther from the arbor. Controls : The controls are generally simple and control the rotational velocity of the lap—the key control—and sometimes the direction of spin, i. The pole must be machined with extreme care to ensure its perpendicularity to the lap. The basic shape of the pavilion has now been created. The other end of the quill is attached to the main head of the assembly. The rough, therefore, needs to be extensively studied so it can be positioned for optimal cutting on the machine. The head can then be lowered by a micro-adjustment and the facet can be cut and re-cut until it is of a desired depth. Drip Tank : The drip tank serves two purposes. Facets at incorrect angles can mean a gemstone that is lifeless or transparent rather than sparkly. Category : Gemstone cutting.

Ultra Tec faceting instruments support both hard and soft stop cutting.

The machine is turned on so the lap begins to spin. Its components are as follows:. With 80 Index Without 80 Index. First the rough stone is glued to the end of the dop. Return to shop. Index Wheel : If you view a gemstone from the top, you will see it has some type of symmetry. The mast assembly is the heart of the faceting machine. The pole must be machined with extreme care to ensure its perpendicularity to the lap. If a round stone with eightfold symmetry is being cut, the index will be set at 0, 8, 16, 24, 32, 40, 48 and 56 for each of the main facets around the stone. Once the facets are prepolished, a final polish can be performed with a gritless lap treated with polishing compound. The height of the mast no longer needs to be set, because it is standard to have every facet be the same depth when faceting a round stone. The mineral in this example is quartz, so the first angle will be 45 degrees. A faceting machine is broadly defined as any device that allows the user to place and polish facets onto a mineral specimen. All orders will be processed in the order they are received and confirmed, and as always we greatly appreciate your business.

I join. All above told the truth. Let's discuss this question. Here or in PM.