Fanuc 21i-t parameter manual

Upload aoaby. Embed Size px x x x x

Warning Warning notices are used in this publication to emphasize that hazardous voltages, currents, temperatures, or other conditions that could cause personal injury exist in this equipment or may be associated with its use. In situations where inattention could cause either personal injury or damage to equipment, a Warning notice is used. Caution Caution notices are used where equipment might be damaged if care is not taken. Note Notes merely call attention to information that is especially significant to understanding and operating the equipment. This document is based on information available at the time of its publication. While efforts have been made to be accurate, the information contained herein does not purport to cover all details or variations in hardware or software, nor to provide for every possible contingency in connection with installation, operation, or maintenance.

Fanuc 21i-t parameter manual

Follow along with the video below to see how to install our site as a web app on your home screen. Note: This feature may not be available in some browsers. This website or its third-party tools process personal data e. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise. How to install the app on iOS. Log in Register. Search titles only. Search Advanced search…. Forums New posts Search forums. Media New media New comments Search media. Everywhere Threads This forum This thread. New posts.

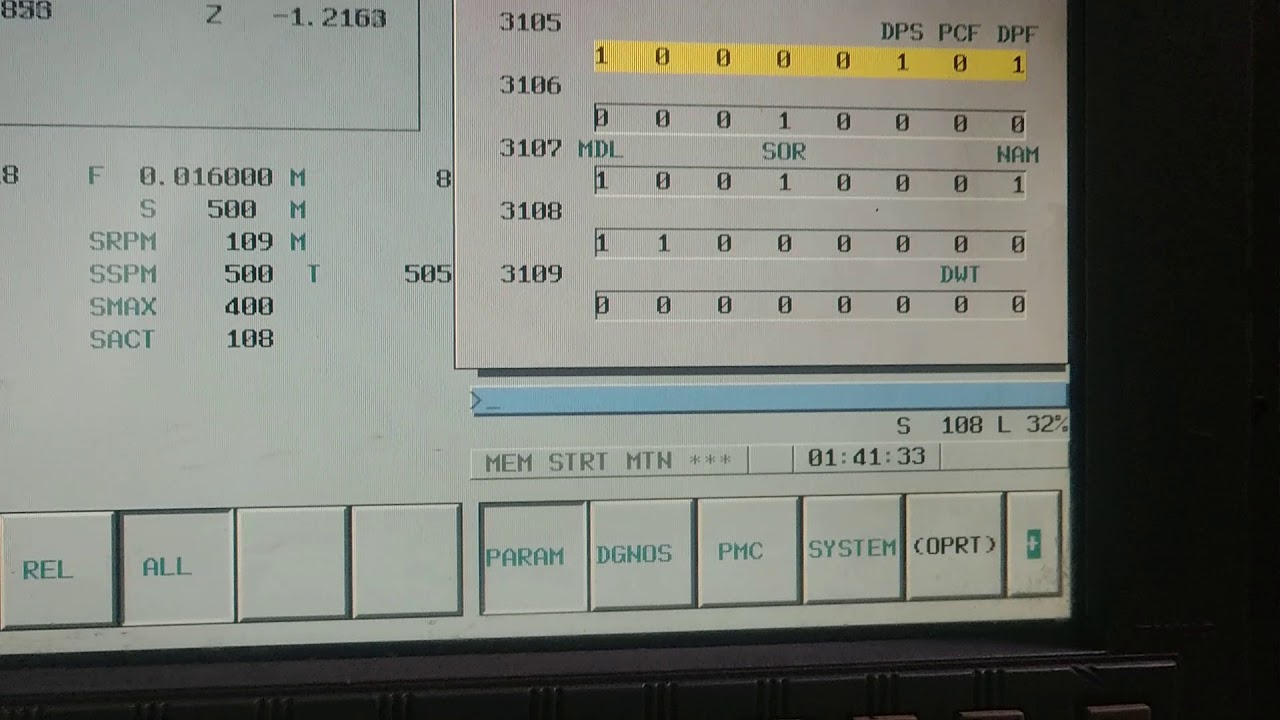

The other use an M code for halffixed angle positioning. XSC, 6 fanuc 21i-t parameter manual parameter No. More precise machining can be performed by changing the backlashcompensating value depending on the feedrate, the rapid traverse or thecutting feed.

.

Warning notices are used in this publication to emphasize that hazardous voltages, currents, temperatures, or other conditions that could cause personal injury exist in this equipment or may be associated with its use. In situations where inattention could cause either personal injury or damage to equipment, a Warning notice is used. Notes merely call attention to information that is especially significant to understanding and operating the equipment. This document is based on information available at the time of its publication. While efforts have been made to be accurate, the information contained herein does not purport to cover all details or variations in hardware or software, nor to provide for every possible contingency in connection with installation, operation, or maintenance. Features may be described herein which are not present in all hardware and software systems. GE Fanuc Automation assumes no obligation of notice to holders of this document with respect to changes subsequently made. GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of the information contained herein. No warranties of merchantability or fitness for purpose shall apply.

Fanuc 21i-t parameter manual

Warning notices are used in this publication to emphasize that hazardous voltages, currents, temperatures, or other conditions that could cause personal injury exist in this equipment or may be associated with its use. In situations where inattention could cause either personal injury or damage to equipment, a Warning notice is used. Notes merely call attention to information that is especially significant to understanding and operating the equipment. This document is based on information available at the time of its publication. While efforts have been made to be accurate, the information contained herein does not purport to cover all details or variations in hardware or software, nor to provide for every possible contingency in connection with installation, operation, or maintenance. Features may be described herein which are not present in all hardware and software systems. GE Fanuc Automation assumes no obligation of notice to holders of this document with respect to changes subsequently made. GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of the information contained herein.

Autographs with coa

This parameter sets the clearance used for peck drilling cycle G To extend the output time of reset signal RST, the time to be added isspecified in this parameter. The head of the program is searched for by the reset and rewind signal. When the reference position setting with mechanical stopper is used, thisparameter sets the feedrate first used to hit the stopper on an axis. QSR Before a multiple repetitive canned cycle G70 to G73 is started, a check to see if the program contains a block that has the sequence number specified in address Q is: 0 : Not made. For input in mm, 0. Sr: The allowable variation width which is obtained by multiplying Sc commanded spindle speed by r constant ratio. A feedrate becomes effective as soon as it has been specified by an F command. Overriding based on this spindle speed is: 0 : Disabled. In the case of specification B:When M codes for specifying a spindle positioning angle arespecified, operations 1 to 3 are performed successively. MVX The axisinmovement signal is set to 0 when: 0 : Distribution for the axis is completed. When a move command is issued only for an axis for which 1 is set in this parameter, the spindle speed reached signal SAR is not checked. When as many characters as the number specified with this parameter areread or punched out, an auxiliary macro is executed once. These parameters require to assign optional software to the CNC and are automatically set depending on the type of the software.

.

NOTEIn polar coordinate interpolation mode, the feedratecomponent for a rotational axis increases as the tool movescloser to the center of a workpiece. Specify L and L1 with radiuses when the Zaxis conforms to radius specification. When GST, 1 of parameter , is set to 0, set the spindle speed during spindle orientation in rpm. T Workpiece zero point offset value in workpiece coordinate system 6 G If an attempt is made to set a tool wear compensation value, theabsolute value of which exceeds the value set in this parameter, thefollowing alarm or warning is output:. Set the servo loop gain multipliers of the spindle for gears 1 to 4. Example2 Servo axis number Parameter No. RWM RWD signal indicating that rewinding is in progress0 : Output only when the tape reader is being rewound by the reset and. Open navigation menu. The following table shows the correspondence between the bits, inputsignals, and commands. F Rp Rp: Programmed radius Then, the actual feedrate is controlled so that the feedrate on the programmed path can achieve the specified feedrate F. If 0 is set, the screen is not cleared. Parameter c 83 S. Do you mean "guide", the conversational side of the control or the "cnc" side?

0 thoughts on “Fanuc 21i-t parameter manual”