Gas pressure when mig welding

Please enter the name by which you would like to log-in and be known on this site. Please enter a password for your user account.

Last Updated on Jan 31 MIG welding is a versatile welding method. They use gas as filler instead of flux for the filler material. Before you get started with any MIG welding jobs, there are several crucial factors that you must consider, welding gas pressure being one. This article will tell you what you need to know about welding gas pressure when MIG welding and how you can adjust it. Read on to learn more! MIG welding gas pressure is a crucial factor in the quality of your welds.

Gas pressure when mig welding

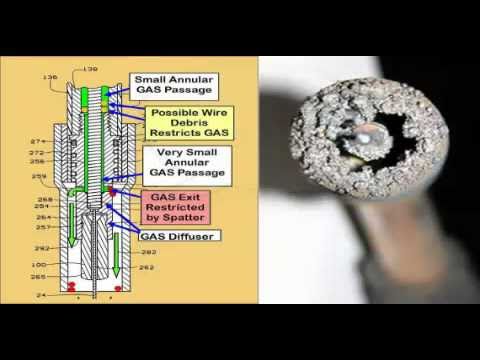

MIG Metal Inert Gas welding is a versatile process that uses an arc between a continuous wire electrode and the base material to produce high-quality welds. A key component is the shielding gas that protects the weld pool from contamination. Setting the optimal gas pressure and flow rate is crucial for proper shielding. Getting the gas pressure wrong can lead to issues like porosity, poor fusion, and excessive spatter. This article will cover the factors that determine ideal MIG welding gas pressure, including:. When MIG welding , you need the right shielding gas to protect that beautiful weld pool. Think of gas as the bouncer at an exclusive club, keeping the riff-raff contaminants out! You can use these solo or mix-and-match to get the right vibe. Some sweet combos:. The goal is to find the perfect posse to keep your weld protected. Too many bouncers create chaos. Start with a pairing like argon and helium, then tweak the ratio from there. Match the properties of the gas to the needs of the material. Now grab your favorite gas buddies and get welding! Now we need to set the pressure!

Stainless steel on the other hand is more difficult to weld, even compared to mild steel.

Forums New posts Search forums. New posts. What's new New posts Latest activity. Log in Register. Search titles only.

A great feature of MIG welding is that it can melt different sized metals together, though it is mainly used for thicker pieces. Setting the gas on a MIG welding set can be simple, requiring limited background knowledge on welding. Today, MIG welding will be explained, and you will also learn how to set shielded gas used for welding. The importance of safety and some of the best shield gases to use will also be discussed. This article will detail how to set the gas on a MIG welding set, and what are the different types of shield gases to use. Different areas or different conditions can affect CFM numbers. The typical gas pressure when welding with MIG tends to be around 3 to 8 psi, this is very low compared to other types of welding. The shielding gas provides the gas needed for MIG welding. When starting, it is important to make sure the gas bottle is properly installed into the holder.

Gas pressure when mig welding

Gas pressure plays a pivotal role in MIG welding, influencing the quality and effectiveness of the weld. Understanding the appropriate levels can significantly enhance weld outcomes. This article delves into the intricacies of determining the optimal gas pressure for MIG welding processes.

Amazon potty

MIG Metal Inert Gas welding is a versatile process that uses an arc between a continuous wire electrode and the base material to produce high-quality welds. Start low. The manual said to adjust the flowmeter to about 5 PSI, which I've done right near the bottom. Learn more. More gas coverage is needed overhead and vertically to envelop the weld properly and back off the pressure for flat welds. This gas also prevents arc strikes when welding thin materials such as sheet metal or pipe. The higher the gas pressure, the more the force against the wire, which will make it penetrate the metal deeper. Start with manufacturer specs, then fine-tune until you find the Goldilocks pressure. Ought to have a dedicated spray bottle hanging close. Many small shops and home hobbyists use a GSS to cut gas use in half. That energy is called "Work Function. Travel speed — a brisk pace needs extra protection to keep up.

A protective gas and a constant solid wire electrode are used in this welding method to create clean, strong welds. When it comes to the success of MIG welding, gas pressure sets are one of the most important ones.

To be on the safe side, make sure that the gas flow rate is always higher than or equal to 15 to 15 CFH. Originally Posted by iroc. Remember I'm green to all this I am just learning. I'm sure it's in LPM. That is called "Resistance Heating. The gas flow setting determines how much gas is sent through your torch and onto your weld puddle. Helium improves heat transfer and penetration. Think of gas as the bouncer at an exclusive club, keeping the riff-raff contaminants out! There are several important factors about MIG welding that you need to be careful about. A good starting point is 20 to 25 CFH. The graph on the left is from a production operation where the gas flow rate at each weld start exceeded 75 CFH for 4 seconds. Ensure the gas flow setting is around 25 to 30 cubic feet per hour CFH for most jobs. Learn more.

In my opinion you are not right. I am assured. I can prove it. Write to me in PM.