Impact sockets vs chrome

Impact wrenches were designed with higher torque in mind — they bust bolts loose impact sockets vs chrome torque them up in excess of foot pounds. It seems natural that when a person uses an impact wrench, they would use an impact socket.

Forums New posts Search forums. Media New media New comments Search media. Members Current visitors New profile posts Search profile posts. The Alliance. The Store. Log in Register.

Impact sockets vs chrome

Are you about to start projects that require sockets? With the different types of sockets available, you must find the right one for your task. But what is the difference between impact and regular sockets, and which socket set do you need? Find out what these two sockets are and how they can help you with your DIY. A socket enables a fastener to be tightened or loosened, and it can be used in different ways to help with your specific task. When in use, the fastener is behind the socket and is used in both machine and electrical tools. Sockets, such as a Bahco socket set , are usually used by DIY experts, mechanics and professionals in the avionics industry. These sockets are designed to be used with an impact driver or powered wrench, meaning they are manufactured with more powerful tools in mind. They need to be able to work despite the vibration that comes from the wrench or hammer. Both individual impact sockets and impact socket sets are black because of the black oxide they are coated in. This coating helps to offer protection against corrosion and is not found on all sockets. These tend to be manufactured with chrome vanadium steel, which is a combination of chromium and vanadium to form an alloy. When considering a regular socket, they can only be used with hand tools. As previously established, regular sockets are made from chrome vanadium steel. This makes it softer and more brittle, which is why it is more likely to break when tools cause vibrations or shock.

As previously established, regular sockets are made from chrome vanadium steel.

Our mission is to empower mechanics to achieve more in everyday projects by providing them with accessible, high-quality tools and accessories that accompany them for a lifetime. What kind of socket are you working with today? Is it a chrome socket or an impact socket? Both socket types have their own set of advantages and specific use cases that will help you to get the job done right. What distinguishes impact sockets vs. Our professional set of impact sockets are forged from industrial-grade Chromium Molybdenum Cr-Mo steel for strength and shatter-resistance, making the tool capable of handling great torque as well as extreme shocks and vibrations delivered by impact guns.

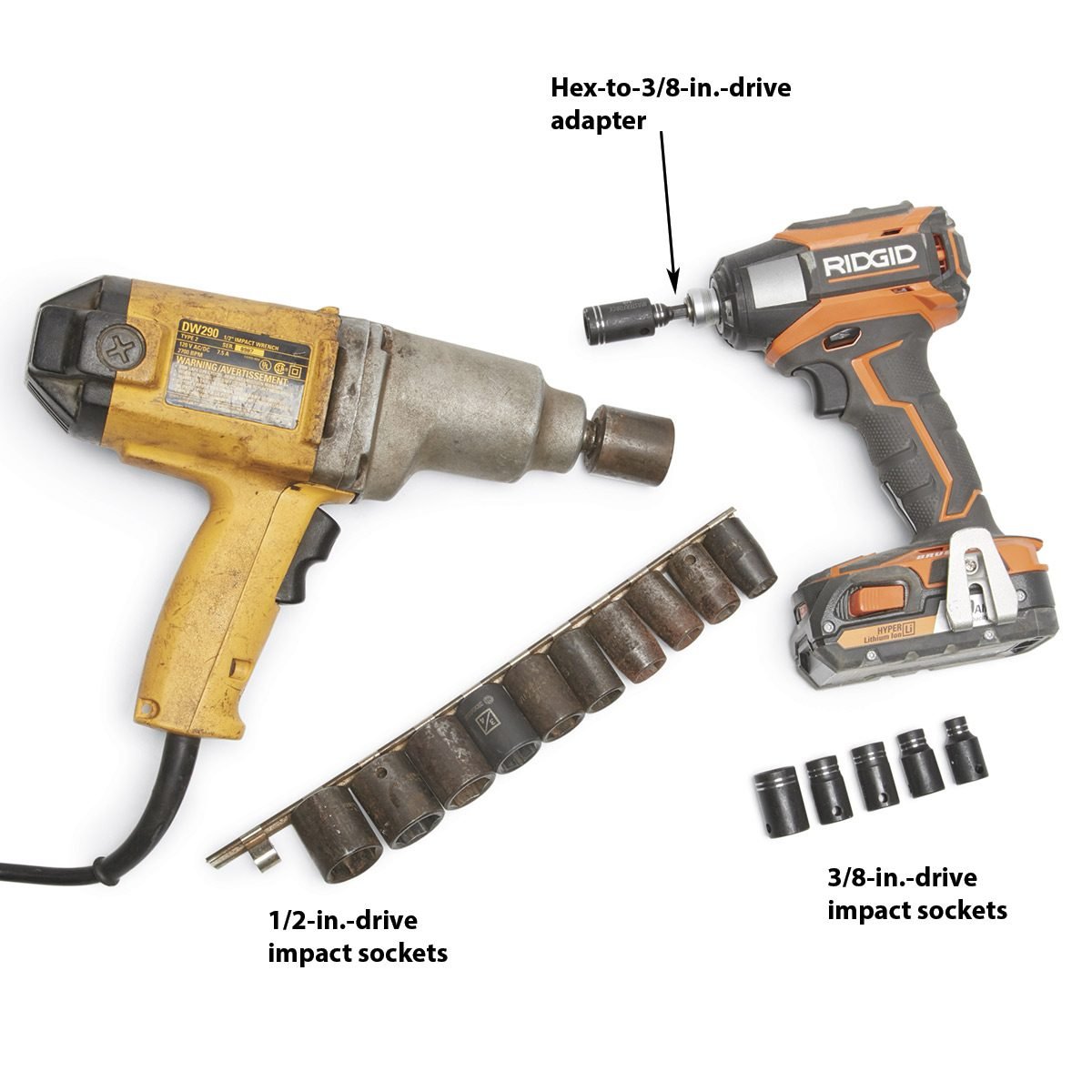

Impact wrenches were designed with higher torque in mind — they bust bolts loose or torque them up in excess of foot pounds. It seems natural that when a person uses an impact wrench, they would use an impact socket. However, we often noticed that technicians are using regular sockets with impact wrenches. Part of this is due to the materials used to make standard sockets and impact sockets. Standard sockets are made from chrome, which is fairly brittle and can split and shatter with too much vibration. Impact sockets are designed to handle the torque and flexibility without the product failing or shattering. It is made from a softer, more malleable material called chrome molybdenum. This material is softer and more flexible to absorb the higher impact in situations where regular sockets would shatter. While it may be convenient to use a standard socket, safety is a major concern. The socket could shatter, sending fragmenting pieces in all directions.

Impact sockets vs chrome

There are many types of power tools that can be found in auto shops and garages around the world. One of the more common types is impact sockets which offer considerable assistance, especially when working with the removal or installation of tires on vehicles. An impact socket is designed to be used with powered impact wrenches or, as they are sometimes called, impact guns. The wrenches themselves are powered pneumatically by compressed air. The wrenches can also be powered through hydraulic oil or by electricity cordless impact wrenches. It is the combination of the impact socket and wrench which creates far greater torque that can be obtained through the use of a manual wrench and socket.

Composite patio set

But if you are using a machine powered impact driving system for intense work, then a normal socket set will most likely shatter or get damaged. Save and share. This could be a serious safety risk for everyone using the same workspace as cracks in the socket could cause it to rupture at any time causing severe injuries. Regular Socket. Q: If X works Account Selector. Whilst regular sockets are corrosion-resistant, impact sockets have an additional finish of black oxide. They are suitable for heavy-duty work, as well as lighter tasks. Chrome is shinny, I like shinny. Both individual impact sockets and impact socket sets are black because of the black oxide they are coated in. Toyo72 Well-known member.

To determine which socket type is suitable for your situation you have to understand the differences between the two.

Whilst impact sockets are more durable, they are also more expensive. If I cant get it out with that, I get out the cheater bar. American Locomotive said:. Due to the additional elasticity of these sockets, they are less likely to break when subjected to high amounts of pressure or torque. I don't like deformed tools. I will probably end up with chromes.. By making impact sockets vibration resistant, they can operate with impact wrenches without breaking and can therefore be used with powered tools. Follow us on socials. M6erfan Well-known member. I use them almost daily with 12v impact and occasionally a ratchet. American Locomotive Well-known member. DFB Well-known member. Save and share.

0 thoughts on “Impact sockets vs chrome”