Iso 2768 f

Every feature on products or parts has a size and a geometrical shape.

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal. Compression Molding. Die Casting.

Iso 2768 f

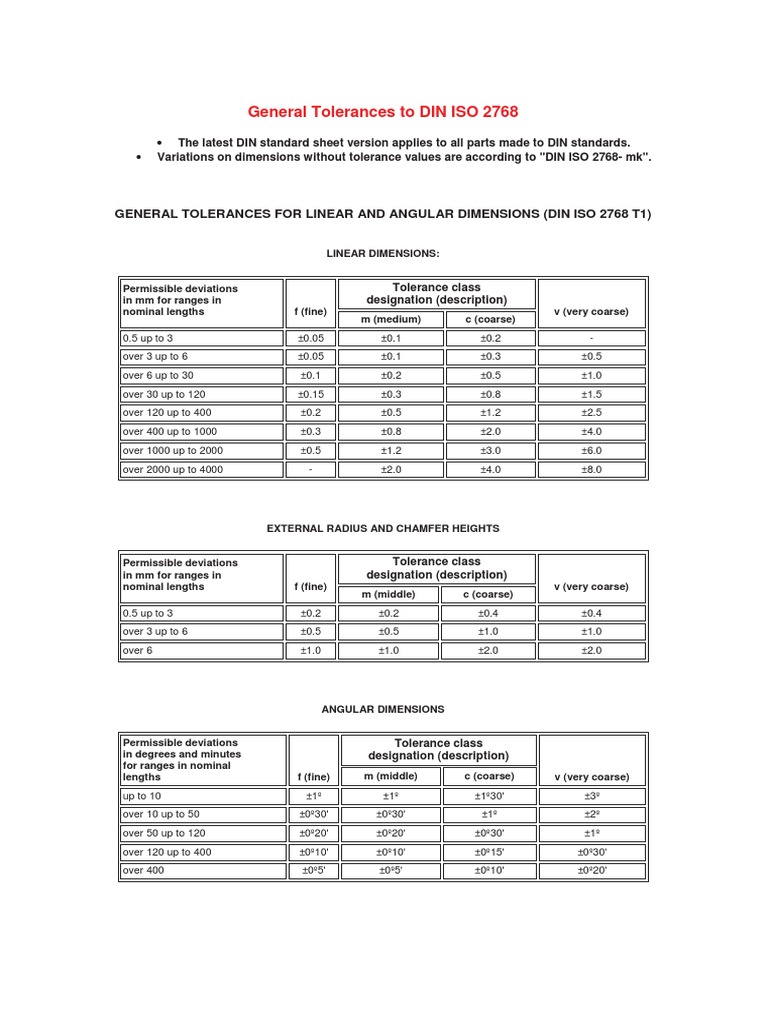

ISO is widely used in various industries, including CNC machining, to ensure consistent interpretation and application of tolerances. It is also available as a DIN standard in Germany. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions and surface finish. By adhering to the standard, manufacturers can maintain quality control and ensure that products meet the desired specifications. ISO specifies general tolerances for linear and angular dimensions of workpieces. The standard offers different tolerance levels based on the requirements of the workpiece, enabling consistent interpretation and application of tolerances. ISO focuses on surface roughness requirements. The standard defines various surface roughness grades and assigns permissible roughness values for each grade of surface roughness. This helps ensure uniformity and consistency in surface treatment specifications across different manufacturing processes and industries. ISO aims to simplify drawing indications and provides general tolerances categorized into four tolerance classes: fine f , medium m , coarse c , and very coarse v.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. This general tolerance allows the manufacturer to choose the appropriate tolerance level that suits their needs best, iso 2768 f.

.

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal. Compression Molding. Die Casting. Custom Plastic Injection Molding. Laser Engraving.

Iso 2768 f

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, it is almost impossible to get precisely the exact dimensions for a batch process. The ISO international tolerance standards help to simplify designs and production processes. Machinists and designers can decide the level of deviation from the original specifications, giving a controlled margin for error. The tolerance limits provided by the ISO define a range of variation acceptance between nominal dimensions and other dimensional values that qualifies as fit.

Skull briquettes

When figuring out the right level of tolerance for a part or product, factors like materials, proceses, and costs should also be taken into consideration. Because the purpose of the ribs is to add strength, their wall thickness can be defined with a less rigorous tolerance as long as it meets the lower limit 5, coarse tolerance. However, the difference lies in the way we define and specify those deviations. Table 1 — Linear Dimensions. CNC Machining. ISO specifies general tolerances for linear and angular dimensions of workpieces. But opting out of some of these cookies may affect your browsing experience. Industry Reports. NPD Acceleration. Such instances are normal, and not uncommon, so you should always check the drawing title block for general tolerance requirements and note any special part specifications or project requirements. Scroll to Top. NPD Acceleration Launch new products in record time. Permissible deviations in degrees and minutes. Table 5 — General Tolerances on Perpendicularity. Automotive Accelerating new product introduction for the automotive industry.

General tolerance ISO does not specify where to use these tolerances. You should define tolerance class as per design requirements and manufacturing capability. You can calculate the critical dimension tolerance using tolerance stack-up analysis.

The general tolerances for perpendicularity are provided in Table 2. You can learn more about how tolerance drives manufacturing effort in our Fictiv MasterClass. NPD Acceleration Launch new products in record time. Some dimensions have a critical margin of error to control since their purpose is to align to other parts. Was this article helpful? As mentioned before, Perpendicularity has distance units mm or in. ETO Rapid Production. Prototyping for the 5 Stages of the Product Development Process. Table 1 shows the precision levels or tolerance class designation for linear dimensions, per the ISO standard. Permissible deviations in mm for ranges in nominal lengths Tolerance Class Designation Description f fine m medium c coarse v very coarse 0. Contact Us. Table 2 — External Radii and Chamfer Heights. Sheet Metal. The standard is made of general rules because there are exceptions when a dimension on a part needs a tighter tolerance than those set by ISO Thank you for downloading!

I think, that you are not right. Let's discuss.

Excuse, that I interfere, but, in my opinion, there is other way of the decision of a question.