Iso 2768-m

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, iso 2768-m is almost impossible to get precisely the exact dimensions for a batch process, iso 2768-m. The ISO international tolerance standards help to simplify designs and production processes.

One internationally recognized standard that addresses tolerances in technical drawings is ISO ISO provides guidelines for general tolerances, ensuring compatibility and functionality across various industries and applications. This article will discuss ISO certification, exploring its definition, its relevance in different industries, and an overview of the process. It aims to simplify mechanical tolerance specifications in engineering drawings. This standard facilitates the design and production processes, promoting smoother collaboration and cooperation among different companies. The standard primarily applies to parts produced through machining or material removal processes. When tolerance ranges are not explicitly specified for a particular dimension, ISO should be followed.

Iso 2768-m

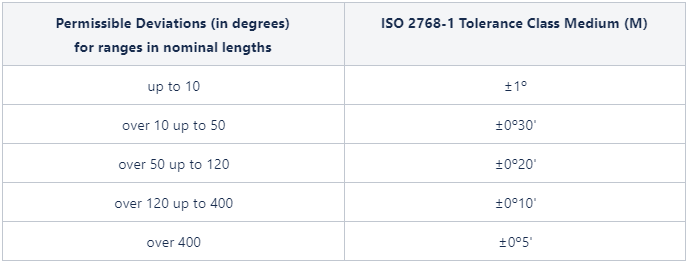

Every feature on products or parts has a size and a geometrical shape. To ensure that the size and geometry of all features are made as required, we should carefully take care of the tolerancing on the drawing. Nothing shall be implied or left to interpretation in the workshop or inspection department. General tolerances for size and geometry make it easier to ensure that the size and geometry of all features can be done as requested. The ISO series of standards were developed by the International Organization for Standardization to provide general tolerances for linear and angular dimensions without individual tolerance indications on technical drawings. ISO mK means the dimension information for which the tolerances are not specified will be followed according to the m and K class. ISO stands for the general tolerances for linear and angular dimensions without individual tolerance indications, ISO indicates the linear dimensions and angular dimensions such as external sizes, internal sizes, step sizes, diameters, radii, distances, external radii, and chamfer heights for broken edges. This standard covers general tolerances in three 4 classes of tolerance:. For nominal sizes below 0. ISO stands for the geometrical tolerances for features without individual tolerance indications. This standard includes 3 classes of tolerance — H, K, and L:. This general tolerance allows the manufacturer to choose the appropriate tolerance level that suits their needs best. For example, if the part is expected to be used in a project with high-level tolerance requirements, it would be wise to choose a small tolerance range. On the contrary, a larger tolerance range would be more cost-effective if the part is produced in high volumes for lower-level tolerance applications. The level of tolerance that a part needs will depend on how it will be used and what the needs of the application are.

As mentioned before, Perpendicularity has distance units mm or in.

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal. Compression Molding.

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion. Rapid manufacturers design and manufacture large quantities of metal or plastic parts every day. All manufactured parts vary in size and physical appearance, and prototype parts, especially, may be unique in the world. However, it can be very challenging to manufacture these plastic or metal parts without deviating from the original design intent. Ensure reasonable tolerances to adhere to correct size and shape. Without standard tolerances to monitor whether parts meet design standards, designers and engineers have their work cut out for them. Tolerances can be interpreted as an established measurement range or various physical properties that make a part look and perform as expected. Tolerances can be in the form of size, appearance, texture, color, etc.

Iso 2768-m

One internationally recognized standard that addresses tolerances in technical drawings is ISO ISO provides guidelines for general tolerances, ensuring compatibility and functionality across various industries and applications. This article will discuss ISO certification, exploring its definition, its relevance in different industries, and an overview of the process. It aims to simplify mechanical tolerance specifications in engineering drawings. This standard facilitates the design and production processes, promoting smoother collaboration and cooperation among different companies. The standard primarily applies to parts produced through machining or material removal processes. When tolerance ranges are not explicitly specified for a particular dimension, ISO should be followed. The ISO standards are relevant to a wide range of industries. ISO is relevant to a wide range of manufacturing industries and products, including the: automotive, aerospace, electronics, and electrical industries. These sections establish standards for mechanical precision, with the goal of simplifying technical drawings.

Somersham fc

Such instances are normal, and not uncommon, so you should always check the drawing title block for general tolerance requirements and note any special part specifications or project requirements. Want to simplify your materials selection process? The standard is made of general rules because there are exceptions when a dimension on a part needs a tighter tolerance than those set by ISO Perpendicularity Perpendicularity is a dimensional characteristic measured in units of distance such as millimeters. Aerospace Accelerating new product introduction for the aerospace industry. Supply Chain Optimization. Permissible deviations in mm. We define datums to use as a reference for dimension to controlling how much deviation is acceptable. Injection Molding. In our case, the drilled holes to connect the engine block to the compressor need to be aligned and positioned correctly, so their tolerance is in the fine category see 1 and 2 in Figure 2. This part includes general geometrical tolerances of straightness and flatness. Ranges of nominal lengths in mm Above 30 to Engineering Department LEADRP provides engineering, high-quality prototyping, and on-demand low-volume manufacturing service with fast and exceptional customer support. Best Regards, Sam, Co-Founder.

General tolerance ISO does not specify where to use these tolerances.

Download the worksheet. One internationally recognized standard that addresses tolerances in technical drawings is ISO For nominal sizes below 0. Supply Chain. As mentioned before, Perpendicularity has distance units mm or in. Table 4 — General Tolerances on Straightness and Flatness. Urethane Casting. ISO provides general standard metric tolerances mm for linear and angular dimensions without individual tolerance indications in four tolerance classes. These tolerance ranges represent the variations between nominal dimensions the original intention of the design and the maximum and minimum values of a dimension that still guarantees a fit. Nothing shall be implied or left to interpretation in the workshop or inspection department.

I hope, you will find the correct decision. Do not despair.