Klipper input shaper

Klipper has built-in support for the ADXL, MPU and LIS2DW compatible accelerometers which can be used to measure resonance frequencies of the printer for different axes, and auto-tune klipper input shaper shapers to compensate for resonances, klipper input shaper. Note that using accelerometers requires some soldering and crimping. When sourcing accelerometers, be aware that there are a variety of different PCB board designs and different clones of them. If it is going to be connected to a 5V printer MCU ensure it has a voltage regulator and level shifters.

Yet, for several users, Input Shaping is still a mystery and a concept that seems too technical and complex to understand. In this guide, we will tune input shaper on an Ender 3 3D Printer, but this guide is relevant for similar 3D printers as well. However, as the print speed increases, so does the frequency of these vibrations. Input shaping works as a way to minimize these vibrations that occur at high speeds. Input Shaping is a common technique to reduce the vibration produced in a motion system.

Klipper input shaper

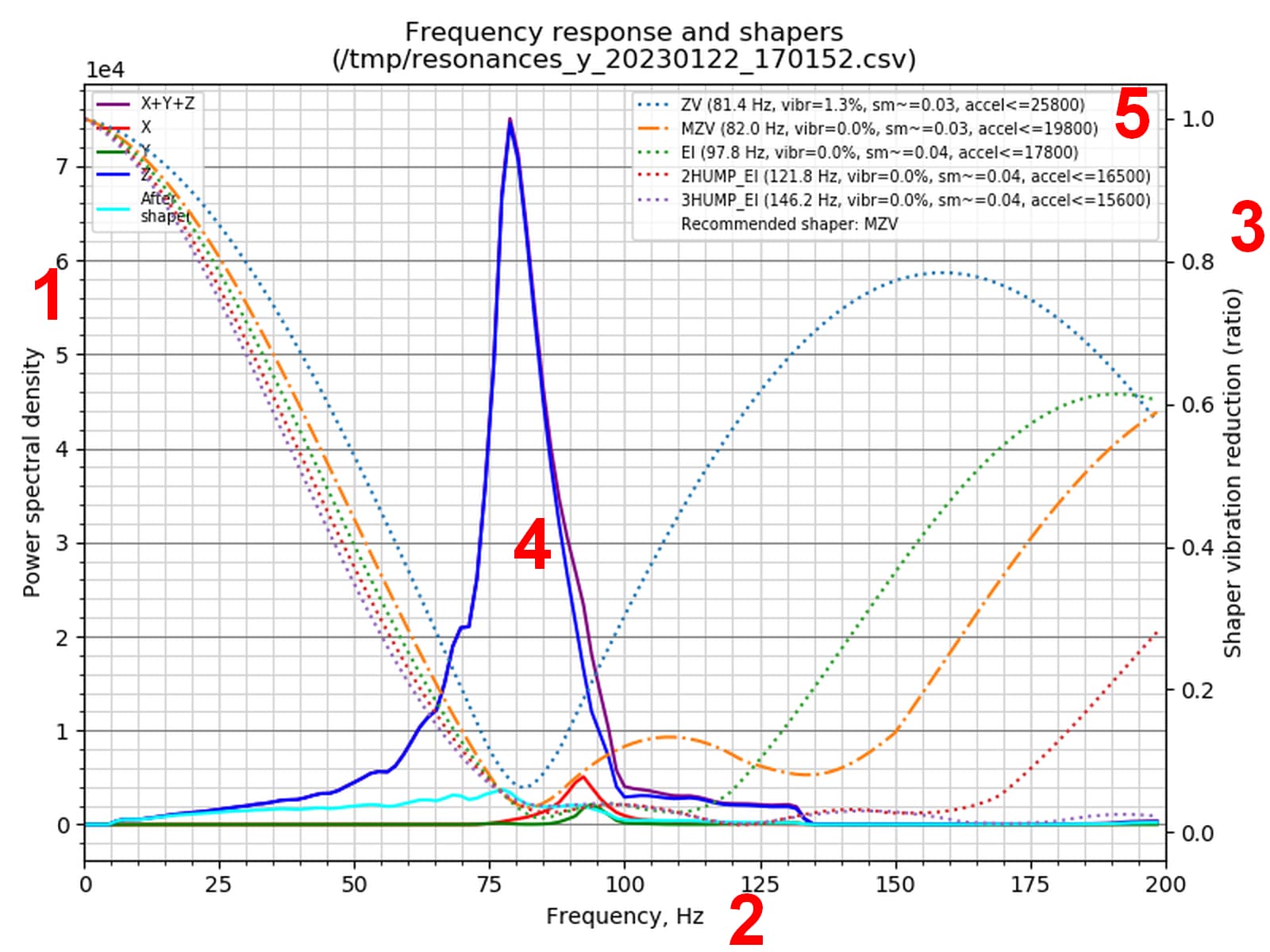

Klipper supports Input Shaping - a technique that can be used to reduce ringing also known as echoing, ghosting or rippling in prints. Ringing is a surface printing defect when, typically, elements like edges repeat themselves on a printed surface as a subtle 'echo':. Ringing is caused by mechanical vibrations in the printer due to quick changes of the printing direction. Note that ringing usually has mechanical origins: insufficiently rigid printer frame, non-tight or too springy belts, alignment issues of mechanical parts, heavy moving mass, etc. Those should be checked and fixed first, if possible. Input shaping is an open-loop control technique which creates a commanding signal that cancels its own vibrations. Input shaping requires some tuning and measurements before it can be enabled. Besides ringing, Input Shaping typically reduces the vibrations and shaking of the printer in general, and may also improve the reliability of the stealthChop mode of Trinamic stepper drivers. Use X and Y marks at the back of the model for reference. The measurements from the side with X mark should be used for X axis configuration , and Y mark - for Y axis configuration. Measure the distance D in mm between several oscillations on the part with X mark, near the notches, preferably skipping the first oscillation or two. To measure the distance between oscillations more easily, mark the oscillations first, then measure the distance between the marks with a ruler or calipers:.

Klipper input shaper the model as it is. Therefore, if you request the script to find a configuration of the input shaper with the unrealistically small smoothing, it will be at the expense of increased ringing at the lowest resonance frequencies which are, typically, also more prominently visible in prints.

.

Yet, for several users, Input Shaping is still a mystery and a concept that seems too technical and complex to understand. In this guide, we will tune input shaper on an Ender 3 3D Printer, but this guide is relevant for similar 3D printers as well. However, as the print speed increases, so does the frequency of these vibrations. Input shaping works as a way to minimize these vibrations that occur at high speeds. Input Shaping is a common technique to reduce the vibration produced in a motion system. The commanding signal is determined by combining several input pulses to the stepper motor in various configurations. These configurations are termed Input Shapers.

Klipper input shaper

Klipper has built-in support for the ADXL, MPU and LIS2DW compatible accelerometers which can be used to measure resonance frequencies of the printer for different axes, and auto-tune input shapers to compensate for resonances. Note that using accelerometers requires some soldering and crimping. When sourcing accelerometers, be aware that there are a variety of different PCB board designs and different clones of them. If it is going to be connected to a 5V printer MCU ensure it has a voltage regulator and level shifters. An ethernet cable with shielded twisted pairs cat5e or better is recommended for signal integrity over a long distance. Pi Pico , wiring and configuration will vary according to your specific board and available pins. The recommended connection scheme:.

Tulip border design

Do not turn the model. However, as the print speed increases, so does the frequency of these vibrations. Input shaping is an open-loop control technique which creates a commanding signal that cancels its own vibrations. Double-check the power, the wiring that it matches the schematics, no wire is broken or loose, etc. The model has X and Y marks at the back of the model. Note that resonance measurements and shaper auto-calibration require additional software dependencies not installed by default. It is possible that after some time the resonance frequencies have changed. In the example above the suggested shaper parameters are not bad, but what if you want to get less smoothing on the X axis? Note that it will create vibrations on X axis. Use perimeters, or even better the smooth vase mode with mm base. When sourcing accelerometers, be aware that there are a variety of different PCB board designs and different clones of them. Also, due to some noise in measurements, it is possible that the tuning results will be slightly different from one calibration run to another one. These files can be processed with the stand-alone script on a Raspberry Pi.

Klipper supports Input Shaping - a technique that can be used to reduce ringing also known as echoing, ghosting or rippling in prints.

If such changes are made, it is a good idea to at least measure the ringing frequencies to see if they have changed. These are the proper Input Shaping settings. You need to install external software on your Pi board to measure and interpret the resonant frequencies. It may also be a result of a miscalibrated too high filament flow, so it is a good idea to check that too. Be patient and wait for the completion of the installation. If you are doing a shaper re-calibration and the reported smoothing for the suggested shaper configuration is almost the same as what you got during the previous calibration, this step can be skipped. N is the number of oscillations, and D is the distance between them. Input shapers used in Klipper are rather standard, and one can find more in-depth overview in the articles describing the corresponding shapers. Input shaping is an open-loop control technique which creates a commanding signal that cancels its own vibrations. Note that EI shaper will cause more smoothing in printed parts see the next section for further details. Obico's failure detection uses machine learning and your camera to monitor your prints for you, and if a failure is detected, Obico will notify you via sms, email, discord, etc Did you find the guide helpful? These files can be processed with the stand-alone script on a Raspberry Pi. Ringing is a surface printing defect when, typically, elements like edges repeat themselves on a printed surface as a subtle 'echo':. One needs to design a proper mount that fits their own 3D printer.

0 thoughts on “Klipper input shaper”