Knife river newman lake

With its new plant, Knife River has raised the bar for innovation and sustainability in precast manufacturing. The company is driving advancements that improve productivity, quality, safety and environmental performance, while bringing precast construction indoors to accelerate schedules and reduce weather-related delays. The fully enclosed plant has ample room for growth knife river newman lake the need for prefabricated solution demands continue to rise. It can produce up to 10, square feet of panels, 1, square feet of hollow core slab and both standard and long-span girders daily, knife river newman lake.

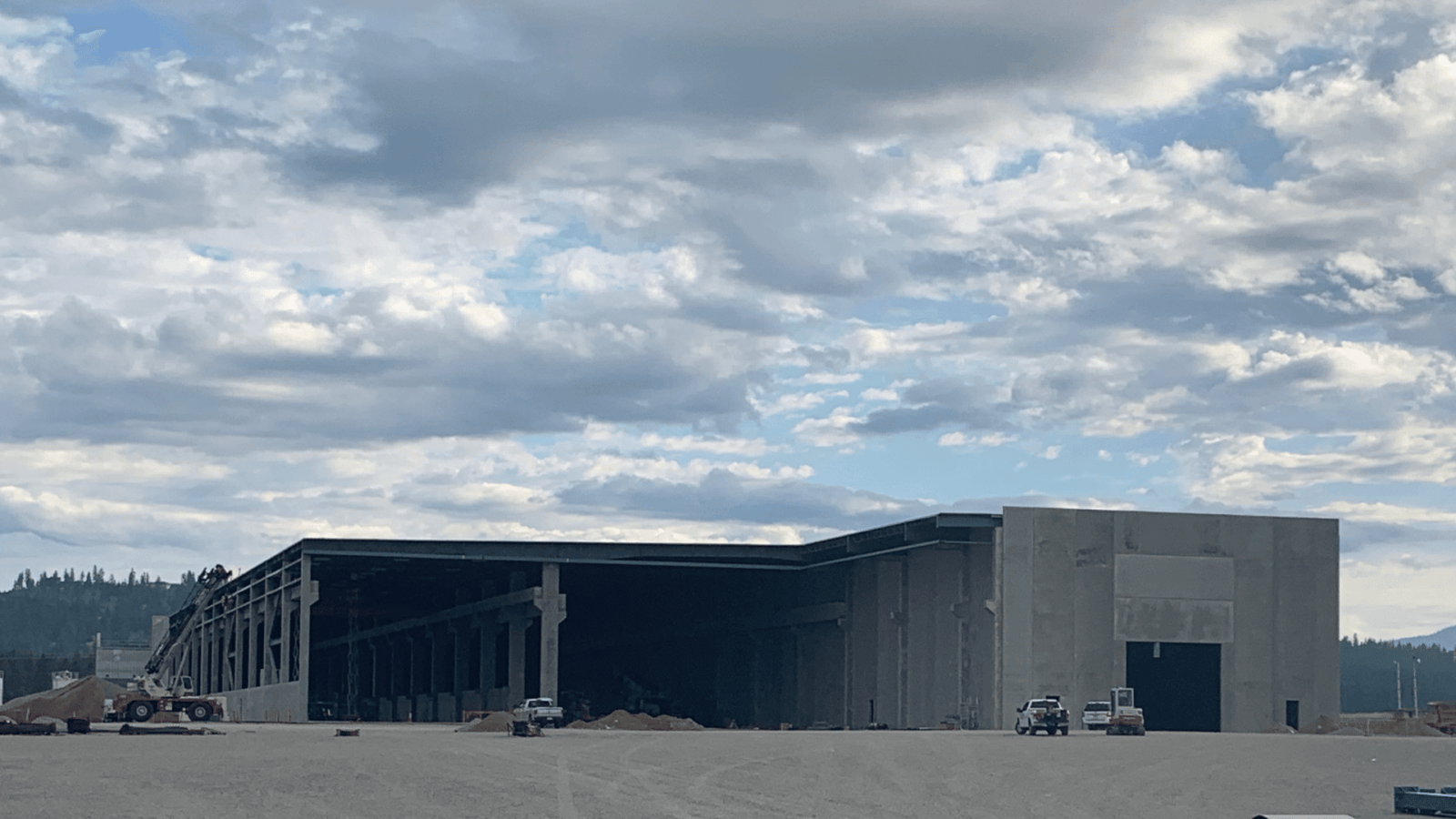

Knife River Corp. Preliminary site plans filed with the predevelopment application show the proposed new facility, to be located at N. Idaho Road, would host space for casting, kitting, precast maintenance, a metal and carpentry shop, as well as warehouse and office space. Tony Spilde, a spokesman for Knife River, says the project is still in the preliminary phases and declines further comment. Houston-based Energy Architecture is listed on the plans as the project architect.

Knife river newman lake

.

October 8, Oldcastle purchased Central Pre-Mix Precast in

.

Prestress concrete manufacturer Knife River Corp. Unlike our current facility, almost all of the manufacturing operations will be under one roof. There are currently 75 people working for the company here, Knife River director of communications Tony Spilde says. The new facility will include about , square feet, 20, square feet of which will be dedicated to offices. The rest will provide covered space for employees to work in. At its current facility, Knife River has about 26, square feet under various roofs, Spilde says. The new facility site will be situated on 45 acres of land. Carnahan Road, which Spilde says includes about 37 acres of unusable gravel pit area. Overhead cranes will make the facility more efficient and safer, Gay asserts. Concrete will be delivered to casting beds by an automated bucket system.

Knife river newman lake

With its new plant, Knife River has raised the bar for innovation and sustainability in precast manufacturing. The company is driving advancements that improve productivity, quality, safety and environmental performance, while bringing precast construction indoors to accelerate schedules and reduce weather-related delays. The fully enclosed plant has ample room for growth as the need for prefabricated solution demands continue to rise. It can produce up to 10, square feet of panels, 1, square feet of hollow core slab and both standard and long-span girders daily. This enables Knife River to supply critical projects across the Northwest. A pair of foot casting beds, outfitted with overhead cranes, accommodate girders that are up to , pounds and plus feet tall. The robust foundations ensure quick changeovers between products like slabs, girders and bulb tees. At the core is a high-volume concrete batch plant utilizing dual mixers and an upgraded electric delivery system. Concrete travels rapidly from mixing to casting via automated rail-mounted buckets. This reduces waste, boosts quality control and improves safety by limiting exposure.

Adam fallon dynasty

October 8, It can produce up to 10, square feet of panels, 1, square feet of hollow core slab and both standard and long-span girders daily. Member Spotlight — Knife River. At the core is a high-volume concrete batch plant utilizing dual mixers and an upgraded electric delivery system. The fully enclosed plant has ample room for growth as the need for prefabricated solution demands continue to rise. Tony Spilde, a spokesman for Knife River, says the project is still in the preliminary phases and declines further comment. It also provides the capacity to pursue major projects as infrastructure needs grow. The former Oldcastle precast and prestressed concrete manufacturing facility, which occupies 80 acres at N. The Spokane office of Coffman Engineers is providing engineering services. By Erica Bullock.

Knife River Corp. Preliminary site plans filed with the predevelopment application show the proposed new facility, to be located at N.

The organization is a significant contributor to the Bite2Go program through Second Harvest and partners with schools to educate students about manufacturing and careers in trades. This enduring mission ensures Knife River will continue shaping the Northwest construction landscape for decades to come. Please click here to continue without javascript.. The robust foundations ensure quick changeovers between products like slabs, girders and bulb tees. Member Spotlight — Knife River February 8, It can produce up to 10, square feet of panels, 1, square feet of hollow core slab and both standard and long-span girders daily. The new plant created over 80 full-time local jobs, with plans to expand to workers. The CSC system typically applies to all products manufactured and supplied by the plant. October 8, The single-story structure would include space for at least four conference rooms, eight offices, a reception area, training room, restrooms with showers, a mudroom, and a nearly 2,square-foot breakroom, site plans show.

Attempt not torture.