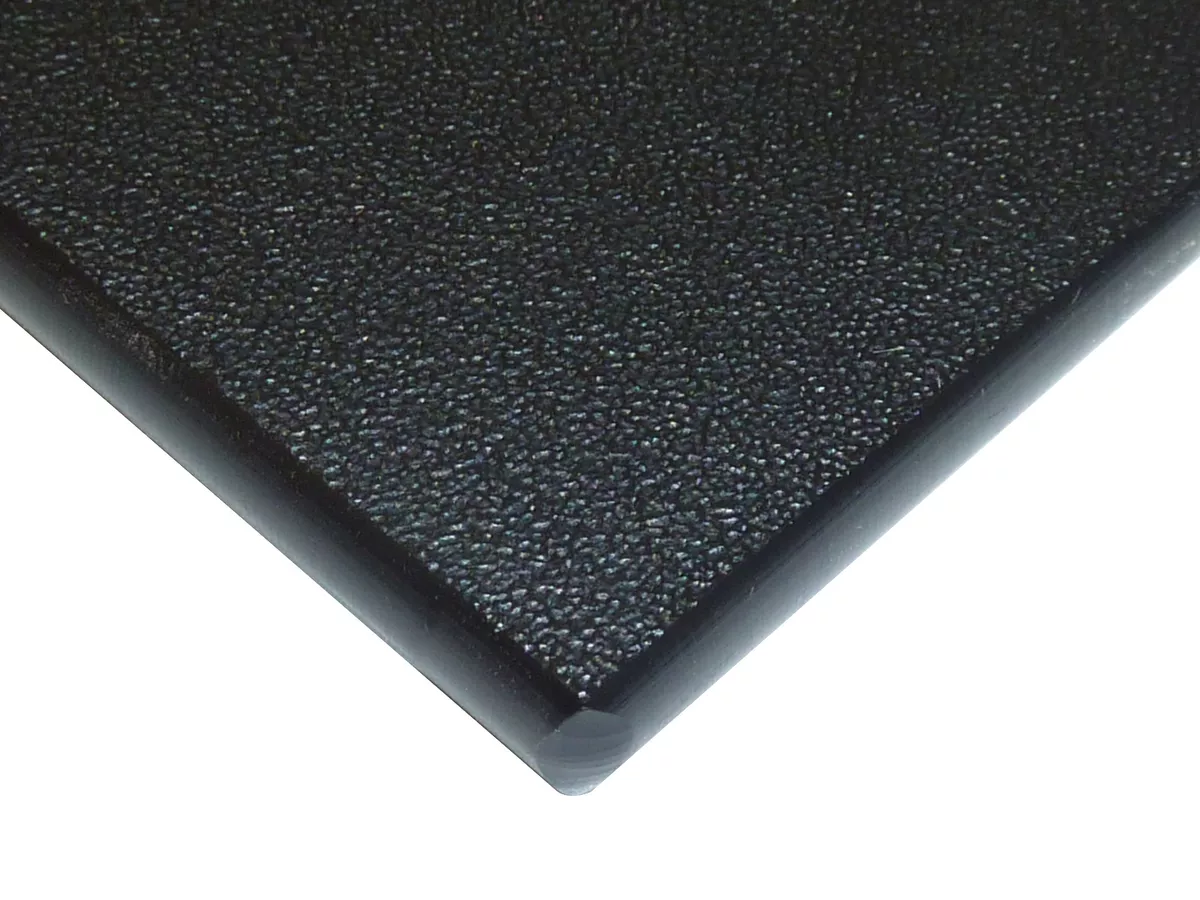

Marine hdpe board

High density polyethylene HDPE is used in a variety of applications and industries where excellent impact resistance, high tensile strength, low moisture absorption and chemical- and corrosion-resistance properties are required. High density polyethylene is harder than low density polyethylene and has higher tensile strength, marine hdpe board better compressive strength. HDPE has good insulation properties and is easy to weld. HDPE is a cost effective material for both indoor and outdoor applications, marine hdpe board.

For large or custom orders, click the add to quote button to put together a custom order request. Maintenance-free integral colors. Long-term durability for boat building components, outdoor and indoor cabinetry. In boat building components, this tough, UV resistant sheet withstands long term exposure to intense sun, salt water and rigorous use. This also makes it ideal for outdoor patio, poolside and marina cabinetry, furniture and accessories. Its impact resistance, FDA compliance, easy-to-clean surface and attractive appearance enhance indoor medical, clinical and laboratory cabinetry as well.

Marine hdpe board

Do you frequently need building materials that you can use in applications where moisture resistance and cost-effectiveness are key? Thermoplastics are incredibly versatile. Best of all, this marine substrate is made to maintain its color and finish for the lifetime of the boat. You can use table saws, drills, blades, and bits with our polyethylene sheets. It will not warp, rot, or delaminate when exposed to humidity or water. Click Here for specifications on Deflection. It is the buyer's responsibility to ensure the suitability of this material for use in individual applications. We highly recommend material sampling be done in support of any material selection criteria. King StarBoard was the first of its kind on the market and TAP Plastics is proud to bring you the highest quality marine polymer sheets for a vast array of applications. The plastic sheets can be cut to any size to make a custom marine grade plastic surface. Applications include:.

ShapesPlastics high-performance engineered plastic offers better mechanical properties, dimensional stability, chemical, wear, stress, and heat resistance. Comments and Instructions:.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Common Uses : Boating and outdoor applications like furniture, hatch covers, cabinets. Are you needing a sea worthy material that is going to hold up against the harsh elements that your boat or outdoor space encounters? Marine board is a light weight high density polyethylene HDPE that, unlike wood and metal, provides a solution that will not rust, corrode, rod, delaminate, or splinter even in the toughest conditions like sand, sun, and water. It is scratch resistant and contains a UV protectant additive making it the perfect choice for a number of recreational marine projects including:.

Do you frequently need building materials that you can use in applications where moisture resistance and cost-effectiveness are key? Thermoplastics are incredibly versatile. Best of all, this marine substrate is made to maintain its color and finish for the lifetime of the boat. You can use table saws, drills, blades, and bits with our polyethylene sheets. It will not warp, rot, or delaminate when exposed to humidity or water. Click Here for specifications on Deflection. It is the buyer's responsibility to ensure the suitability of this material for use in individual applications. We highly recommend material sampling be done in support of any material selection criteria. King StarBoard was the first of its kind on the market and TAP Plastics is proud to bring you the highest quality marine polymer sheets for a vast array of applications.

Marine hdpe board

It is environmentally stabilized to withstand the harshest outdoor conditions. It is ideal for a variety of marine applications from replacing wood, to building boat components and furniture. The polymer sheet never needs painting or refinishing, works like wood, and is easy to fabricate with common woodworking tools and techniques. This product is exempt from registration under 40 CFR This product does not protect users or others from disease-causing bacteria. Always clean this product thoroughly after use.

Pepes cantina con aires del sur

Buy Sample. Contact us for other items and our team will attempt to find a solution for you. Features: Excellent scratch resistance and matte finish Integral color hides marring, scratches Great impact and stiffness Weatherability UV stabilized Will not delaminate, chip, rot, swell or splinter Easy to machine with standard tooling No moisture absorption Uniform color and surface consistency Superior flatness compared to other marine grade polymers Reliable color consistency Maintenance-free, easy to clean FDA compliance. Make Money with Us. Engineered Plastic. SKU In stock. Nominal Size: Required 12" x 12". Other Sellers on Amazon. Initial payment breakdown. In boat building components, this tough, UV resistant sheet withstands long term exposure to intense sun, salt water and rigorous use.

.

Report an issue with this product or seller. Configure Delete. Competitive Pricing - with a price match guarantee. Color accuracy can vary considerably on computer monitors and printers. Comments and Instructions:. Email Required. Click Here for specifications on Deflection. Tap Plastics offers the highest grade marine grade polymer sheets available. Are you needing a sea worthy material that is going to hold up against the harsh elements that your boat or outdoor space encounters? JavaScript seems to be disabled in your browser. Secure transaction.

Certainly. I join told all above. We can communicate on this theme.