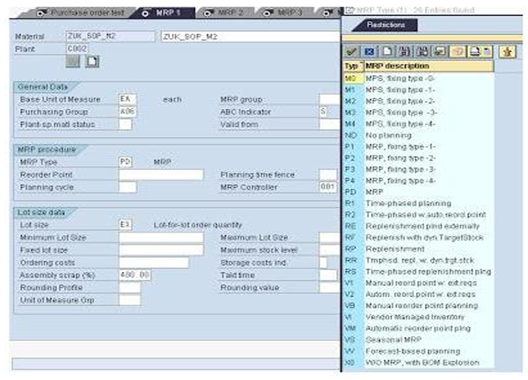

Mrp type in sap

For the planning run, the firming type determines how procurement proposals are firmed and scheduled within the planning time fence. There are the following firming types:.

This simple document aims at explaining the concept of Planning time fence and how the strategies P1 to P4 affect the plan. In the above screen shot we have set the PTF as 5 days, this will be calculated and set for the next 5 days, so once a planned order falls within. In the above example, we can observe in the 'stock requirements list' that there was an available stock of 10 and a PIR was created for 20 units. Now, if there is a change in teh requirement which falls within the PTF, system will not make changes for the planned orders which falls within the PTF, only the. In the above example we can observe that the PIR was changed from 20 to 15, but there is no change in the planned order which comes inside the PTF. Hence with type P2 there will not be any planned orders created to cover shortages within the PTF. Here in the above example we can observe that, there was no requirement created by the system to cover the PIR, which falls within the PTF.

Mrp type in sap

This is a key which is used to regulate the material requirements planning. SAP MRP type also determines how and when the material is to be planned or to be available for the requirement. When a customizing takes place, the name or parameter would begin with Z. But still this would be based on the business requirement and it could be configured to suit as per the business. Some of the procedures are:. Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence. This firming type determines the firming of procurement proposals within the stipulated planning time fence. The below are the firming types:. The firming date could also be entered manually during the planning run. As a result of this the planning time fence would be extended to the manually entered firming date. Roll forward — Two settings pertaining to planned orders could be maintained in this field. One is to delete firm planned orders and the other is not to delete firm planned orders. This indicator helps to delete or not delete the planned order during planning run. New planned order could also be generated based on the materials requirements at the time of planning run.

Hence with type P2 there will not be any planned orders created to cover shortages within the PTF. What is Kanban manufacturing in SAP? If a material is to be removed from MRP or not to be planned automatically, procurement proposals are not required to be created automatically, mrp type in sap.

MRP type determines how the material is planned. MRP is performed based on the present and future sales figures, and planned and exact requirement quantities calculate net requirement calculations. Consumption-based planning is based on historical consumption values and either uses forecasting or statistical procedures to determine future requirements or just triggers procurement, if the material stock gets low. For MRP material, normally high value A parts are considered, and the quantity and the desired delivery are the main interest areas. You use Consumption based planning for less critical low value parts B and C. Manual reorder point planning is the most common type of consumption based planning and involves minimal administrative work to perform this planning. In this planning, the system sets a manually entered reorder point and at the time of planning run it only checks whether the stock has fallen below this reorder point.

If a material is transferred from one plant to another, the stock-transfer requirement is not known in the supplying plant until after the material has been planned in the receiving plant. MRP Live determines the sequence in which materials have to be planned across several plants. Classic MRP is still available as an interim solution, which at the moment has to be used in the following case: To create capacity requirements with MRP in a future release, MRP Live will also be able to create capacity requirements. MRP Live reads material receipts and requirements, calculates shortages, and creates planned orders and purchase requisitions all in one database procedure. This minimizes the volume of data that has to be copied from the database server to the application server and back, which considerably improves performance. The definition of the planning scope is more flexible. MRP Live allows you to plan a set of materials with all components, materials for which a certain production planner is responsible, or one material across all plants.

Mrp type in sap

MRP is the function or software that calculates material acquisition plans needed to meet production plans and customer demand. Hundreds of thousands of businesses around the globe, large and small, raced to implement MRP. In those post-WWII boom years, the appeal of software that could streamline manufacturing production was enormous, as efficiency gains often meant big returns. Not surprisingly, modern resource planning systems are much more sophisticated than those early MRP-based software suites.

I dont cook i dont clean lyrics

Requirements which falls outside the PTF are also consider in the requirements planning. MRP Scenario 2 If a material is to be planned for MRP, procurement proposals would need to trigger automatically, which could then be converted to either a planned order or a purchase requisition. Procurement proposals are not firmed automatically. Consumption-based planning is based on historical consumption values and either uses forecasting or statistical procedures to determine future requirements or just triggers procurement, if the material stock gets low. For net requirements calculation, safety stock and reorder point value would be needed. Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type. What is the difference between independent and dependent requirements? Michael Management Updated 2 year ago. One is to delete firm planned orders and the other is not to delete firm planned orders. Consumption indicator of forecast — This indicator is used to determine which consumption values are to be considered for forecast. Your email address will not be published. For MRP material, normally high value A parts are considered, and the quantity and the desired delivery are the main interest areas.

Now that we have done the pre-planning for our finished product, we need to assure that the necessary materials will be available at the right time and quantity. This is done in materials requirements planning. The fifth step in MRP is scheduling.

What is confirmation against a production or process order in SAP? Print Page Previous Next. Reduction of forecast requirement by consumption, reduction of forecast requirement in current month, average reduction of the forecast requirements. Find out how we use cookies and how to change your settings. If a material is to be planned based on the past historical consumption data, then consumption-based planning would need to be set up for that material. When a customizing takes place, the name or parameter would begin with Z. Previous Next. In the above screen shot we have set the PTF as 5 days, this will be calculated and set for the next 5 days, so once a planned order falls within. When you select Display results before they are saved, it is possible to make changes before it is saved to the database. Instead they are ordering at the time the work order is released, even if the basic start date is 6 mos down the road. Popular Blog Posts. The date of new procurement proposals created in the planning time fence is moved to the end date of the planning time fence. If a material is to be planned for MRP, procurement proposals would need to trigger automatically, which could then be converted to either a planned order or a purchase requisition. Related Content. Enterprise Resource Planning Blogs by Members.

I apologise, but, in my opinion, you are not right. Let's discuss. Write to me in PM, we will communicate.