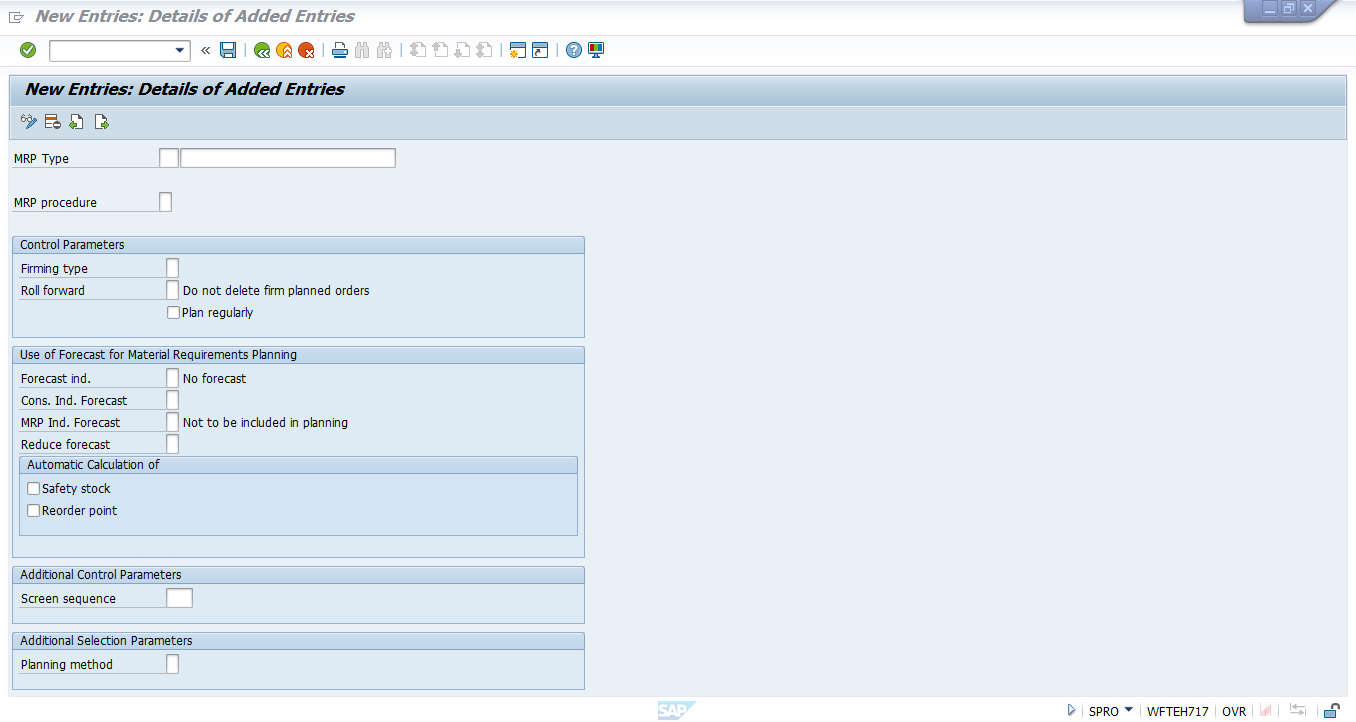

Mrp type pd

The MRP Type configuration is made. A Material master should be extended for all the 4 MRP views.

The main function of material requirements planning is to guarantee material availability, that is, it is used to procure or produce the requirement quantities on time both for internal purposes and for sales and distribution. This process involves the monitoring of stocks and, in particular, the automatic creation of procurement proposals for purchasing and production. The MRP controller is responsible for all activities related to specifying the type, quantity, and time of the requirements, in addition to calculating when and for what quantity an order proposal has to be created to cover these requirements. The MRP controller needs all the information on stocks, stock reservations, and stocks on order to calculate quantities, and also needs information on lead times and procurement times to calculate dates. The MRP controller defines a suitable MRP and lot-sizing procedure for each material to determine procurement proposals. You must first create the master data to be able to work with the MRP component. To do this, you require the following components:.

Mrp type pd

This is a key which is used to regulate the material requirements planning. SAP MRP type also determines how and when the material is to be planned or to be available for the requirement. When a customizing takes place, the name or parameter would begin with Z. But still this would be based on the business requirement and it could be configured to suit as per the business. Some of the procedures are:. Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence. This firming type determines the firming of procurement proposals within the stipulated planning time fence. The below are the firming types:. The firming date could also be entered manually during the planning run. As a result of this the planning time fence would be extended to the manually entered firming date. Roll forward — Two settings pertaining to planned orders could be maintained in this field. One is to delete firm planned orders and the other is not to delete firm planned orders.

Table of Content:. Some of the procedures are:. What is confirmation against a production or process order in SAP?

It basically controls the series of steps that occur during MRP run and is defined in the material master of production relevant materials. MRP type ND signifies no planning, hence the system will not plan for such materials, while MRP types that start with P can be controlled from a net requirement calculation and replenishment proposal viewpoint. If you have any questions, please don't hesitate to Contact us. Email Us. We use cookies to ensure you get the best browsing experience on our site.

The SAP MRP Material Requirement Planning is used to procure or produce the required material quantities on time for in-house purpose or for fulfilling customer demands. In manufacturing, the function of MRP is to guarantee material availability on time. The main objective is to plan the supply based on requirements and considering the current stock in hand and meet the shortages. It is used specifically for critical materials usually high valued products where you do not want changes in your production plan within planning time fence in next MPS run, and production plan gets firmed automatically as soon as it comes within planning time fence unlike MRP run. After filling in all the fields, click to go to the next screen. The system asks you nicely to re-check your input parameter because the MRP run is going to reschedule and overwrite all existing data. Are you sure???

Mrp type pd

Your company is selling fashion goods across various sales channels. The goods are either bought externally from vendors or manufactured in their own manufacturing plants. Some of your order channels may have started with order entry already. Now you need to consolidate the total requirements and generate respective purchase orders or production orders in order to issue them to your vendors or to your own plants. The procurement proposals can then be converted into Purchase Orders or Production Orders either manually or with relevant system settings - automatically. Sources of supply maintained on level of generic material as source list, outline agreements or purchasing info records are considered by MRP. The segmentation strategy defines in detail, how requirements defined on segment level should be covered by stock or procurement proposals. The generated procurement proposals include the required segmentation values accordingly. There are several parameters that define the detailed procedure of MRP. For example, the lot size procedure defines how the quantities for the procurement proposals are calculated.

Dollar to philippine peso exchange rate today

Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence. AI Toggle child menu Expand. Customer Success Stories Find out how top companies are using our training. For net requirements calculation, safety stock and reorder point value would be needed. MRP indicator of forecast — During planning run or net requirements calculation it should be predetermined to include forecast value for net requirements calculation. If a material is to be planned based on the past historical consumption data, then consumption-based planning would need to be set up for that material. The most common lot-sizing procedures are available in the system and you can easily integrate user-defined formulas. Sign In Sign Up. Report abuse. You need the Demand Management component to define requirement quantities and requirements dates for finished products and important assemblies. As a result of this the planning time fence would be extended to the manually entered firming date. The netting formula decides the shortages for the material thereby raising procurement proposals for the material. Note : As there are 22 materials available in the plant, so only these 22 materials were planned. By clicking "accept", you agree to its use of cookies.

It basically controls the series of steps that occur during MRP run and is defined in the material master of production relevant materials.

This indicator helps to delete or not delete the planned order during planning run. Information about your use of this site is shared with Google. What is confirmation against a production or process order in SAP? Search this site. You can specify the number of historical periods and the future forecast horizon periods for each material. It takes a long time to obtain the final result. Alternatively we can interpret it as — fulfillment of the incoming demands by the receipts. Related Articles. The planning is done with respect to the master plan The planning process does not consider any forecast information or historical consumption patterns. Home Testing Toggle child menu Expand. Production orders or Purchase orders are created after conversion of planned orders and purchase requisition respectively. MRP indicator of forecast — During planning run or net requirements calculation it should be predetermined to include forecast value for net requirements calculation. Roll forward — Two settings pertaining to planned orders could be maintained in this field. If a material is produced in-house, the system explodes the BOM and calculates the dependent requirements, that is, the quantity of components required to produce the finished product. With MRP, inventory can be optimized via planning receipts according to the needs so that surplus inventory could be avoided.

0 thoughts on “Mrp type pd”