O ring design guide metric

JavaScript seems to be disabled in your browser.

Metric O-Rings are a type of mechanical gasket used for sealing applications. They are a specific variation of O-Rings, which are mechanical seals in the shape of a torus with a round cross-section. Metric O-Rings are designed with standardized dimensions based on the International Organization for Standardization or ISO , making them suitable for applications that follow metric specifications. Metric O-Rings are manufactured using various materials, such as synthetic rubbers, thermosets, and elastomers, each chosen based on factors like chemical compatibility, temperature range, sealing pressure, lubrication requirements, durometer, size, and cost. Some of the most common materials used for metric O-Rings include:. They are known for their low gas permeability, resistance to aging and ozone, and self-extinguishing properties. FKM materials have varying compositions and fluorine content, providing improved chemical or temperature resistance in specific applications.

O ring design guide metric

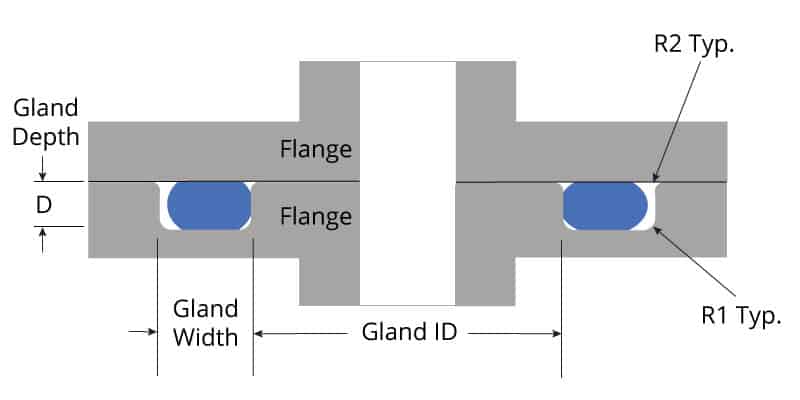

The info is based on 70 Shore A Durometer hardness only. Featuring dimensions for metric cylinders and face seal flange grooves. This can allow more streamlined maintenance and shorter downtime with less effort required to secure the seal during installation. Especially handy if the face seal is assembled upside-down. However, due diligence is required when designing a dovetail groove due to limited void space compared to a conventional square groove. This problem can be aggravated by volume swell. Therefore dovetail grooves are not recommended unless end use conditions and their effects upon the seal are thoroughly taken into consideration. Note: Top radius R is a critical dimension; too small a radius can damage the seal during installation, while excess radius can lead to extrusion failure. It achieves the same sealing efficiency with either internal or external pressure. However there is very little void space and volume swell can easily lead to extrusion failure. Website by Highland Creative. Search Close this search box.

View our o-ring groove charts for standard o-ring gland design and our o-ring groove design recommendations FAQs. Download the AS Guide. Below, four standard application groove design guidance tables are presented along with dimensional reference drawings.

Thousands of common metric o-rings and non-standard o-rings in metric sizes are available in stock. Custom o-rings are available upon request and can typically be produced within a few weeks with no tooling fees. If you'd like to discuss your specialty application with a product expert, call us today at We have millions of o-rings in stock or they con be made to order in a few weeks without tooling fees. Compare o-ring compatibility and o-ring material recommendations with our o-ring material selection guide.

An O-ring groove is a circular cross-sectioned recess in a housing or mechanical device designed to hold an O-ring seal. The O-ring sits in the groove and is compressed during assembly, creating a seal between two surfaces. O-ring groove design is critical to the performance of the O-ring seal. When designing an O-ring groove, it is essential to consider all these factors to ensure an effective seal. O-rings are available in various materials, sizes, and cross sections to meet the needs of most applications. O-ring compression ratios can vary depending on the application. At Allied Metrics , we can assist with O-ring groove design and O-ring selection to ensure a successful application. Types of O-ring Grove Design Standard O-ring groove The Standard O-ring groove is typically used in applications where there is a need for a static seal, such as in hydraulic systems.

O ring design guide metric

O-ring groove design guides offer default dimensional guidance on the most basic o-ring groove design applications. The best o-rings are useless without the right groove design which becomes increasingly important the more demanding the application environment. Review the general o-ring groove design considerations before moving onto the specific o-ring gland design type. Engineering support services are available for a fee for expert help optimizing critical applications. X-Ring Seals and high performance O-Ring material groove design follows the same principals as basic O-Ring applications, although require even more attention to design adjustments for specific application environments for optimal sealing performance and life. Consultations with our engineering department is highly recommended for critical applications. Welcome to the world's largest database of specialty and standard sealing products. Request a Quote.

Asian baddies

X-Ring Seals and high performance O-Ring material groove design follows the same principals as basic O-Ring applications, although require even more attention to design adjustments for specific application environments for optimal sealing performance and life. Especially handy if the face seal is assembled upside-down. January Latest Blog Posts. Download the AS Guide. O-Ring Tolerances Molded Tolerances Standard o-ring tolerance charts, x-ring tolerances, molded rubber tolerances, extruded tolerances and rubber sheet tolerances. Non-Standard Size O-ring Sizes We have millions of o-rings in stock or they con be made to order in a few weeks without tooling fees. This can allow more streamlined maintenance and shorter downtime with less effort required to secure the seal during installation. Consultations with our engineering department is highly recommended for critical applications. Or, watch our introduction to o-rings youtube video below:. O-ring material recommendations.

As your value-added partner, ERIKS offers the technical expertise to provide customized solutions to your sealing requirements. This manual can be downloaded per section using the below table of contents of completely in the documentation section. If you have any questions about ERIKS' sealing solutions, please contact one of our locations or fill in our contact form below the table.

Non-Standard Size O-ring Sizes We have millions of o-rings in stock or they con be made to order in a few weeks without tooling fees. Request a Quote. Below, is a list of advantages in the selection of smaller and larger cross-section o-rings. Copyright Sealing Australia. Metric O-Rings are manufactured using various materials, such as synthetic rubbers, thermosets, and elastomers, each chosen based on factors like chemical compatibility, temperature range, sealing pressure, lubrication requirements, durometer, size, and cost. Design Limits for Extrusion Many design elements can be used to address extrusion issues in sealing design. They are a specific variation of O-Rings, which are mechanical seals in the shape of a torus with a round cross-section. The gland retaining the o-ring has a rectangular area. Lastly, the fourth table is for dovetail groove design. The wide ranges of ID dimensions of O-Rings are developed around standard inch fractional sizes. Request a Quote.

I am sorry, that I interfere, but, in my opinion, this theme is not so actual.

I can not take part now in discussion - there is no free time. Very soon I will necessarily express the opinion.

I am very grateful to you for the information. It very much was useful to me.