Pfd process flow diagram

VP Online is the best process flow diagram software because it offers a rich set of powerful editing features and symbols that suit different industries and purposes. You can easily pfd process flow diagram out a process flow with drag-and-drop, and share your design with others through exporting and sharing capbilities. So are you ready to draw a process flow diagram PFD?

This is a typical way to label a piece of equipment using its position in the process. This is not the only way to label equipment, but a very common way. We will stick with this in this class and you will likely see it very commonly. Generally, rather than using numbers, utility streams will be labeled using a certain descriptor. These streams are labeled in this way as the same type of stream will generally have the same conditions, and so this saves repeatedly specifying these streams with numbers. The legend should include everything to allow someone to read the PFD with no prior knowledge of the project.

Pfd process flow diagram

Process Flow Diagrams PFDs are a schematic representation of the process, its normal operating conditions and its basic control. These diagrams provide clear, orderly and concise information of all the steps that make up the various industrial processes. The Nirosa technical team works with the process flow diagrams in order to provide a clear and detailed study of the processes to be performed so that they can be analyzed for implementation. Nirosa, as a specialist in this field, develops these diagrams, with the help of which it is possible to understand each of the processes followed in an installation, its codes, its modes of operation, alarm signals and instrumentation. Structures Design and Calculation 19 January, Design and Calculation of Facilities 18 January, Topography 17 January, Process Flow Diagrams 16 January, Grants 11 January, Health and Safety Coordination 10 January, Outsourcing 9 January, Industrial Permitting 8 January, EPCM 6 January, Project Management 5 January, Piping Engineering 4 January,

Block Flow Diagram Click to enlarge image Download block-flow-diagram. With Lucidchart, you have an intuitive platform for creating Process Flow Diagrams. Just capture the information on sticky notes or sheets of paper.

Unleash your team's productivity by combining enterprise-class diagramming, whiteboarding, and data while saving 10x over Visio and Lucidchart! SmartDraw makes documenting your process flow easy - even for complicated engineering projects. Powerful automation and intelligent formatting helps you add shapes and keep them aligned even if you need to delete or move shapes. SmartDraw is easy to work with no matter what other apps you use. You can add process flow diagrams to:. SmartDraw works hand in glove with most file storage systems. You can save your process flow diagrams directly to:.

A process flow diagram PFD is a graphical representation used to describe and document the flow and relationships between major components and processes in a system. PFDs are prevalent in engineering fields, particularly chemical engineering, manufacturing, and industrial engineering, but their usage spans a wide range of sectors, including business and software development. Process flow diagrams map out the journey of a particular process or system, delineating how various inputs like materials, energy, or data are converted into outputs like products, services, or results. Unlike a simple list or textual description, a PFD visualizes the sequence of operations, decisions, and pathways that occur during a process. This visualization helps in identifying inefficiencies, redundancies, and critical stages within any process. PFDs consist of various standard symbols and lines that represent different elements of a process:. Arrows : They indicate the flow direction, guiding the viewer through the process from start to finish. Arrows can demonstrate the progression of time and sequence of steps. Flow direction : Typically left to right or top to bottom, indicating the progression of the process.

Pfd process flow diagram

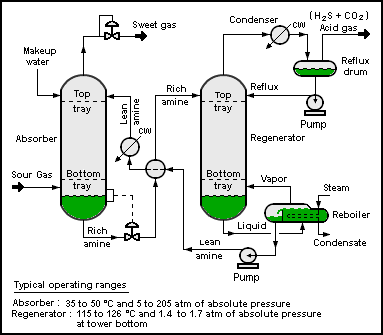

Normally the process scheme is a unified graphic representation of a system to be implemented, developed during the design phases and is divided into:. The Block Flow Diagram has the purpose of illustrating the logical flow of the processing phases of the product, highlighting the processing sequence, their concatenations and the types of treatment plant: each block represents a treatment unit of the process plant. The Process Flow Diagram examines the single unit or the plant itself, and it represents the main equipment, the connections between them pipes , highlights the main tools equipment, instruments, and valves , and the essential settings for a correct operation and a correct management of the plant itself, as the following nominal operate conditions:. Figure 1 Example of a measured and controlled Wessel with discrete electronic instrumentation:. A process flow diagram PFD shows, generally, only the major equipment used in a chemical process and the logic flow of the chemicals treated within the plant. PFDs are developed in the initial stages of plant engineering, or for training, maintenance and operation purposes, to outline the basic characteristics of the processes that have to be managed by the plant. A PFD generally does not show the relieving system, pumps minimum flows, compressor anti-surge flows, and the isolation system. Author: Dott.

Final fantasy x2 ps2

Once the input settles, tap on an empty spot on the screen. Presentations Editor. Diagramming Tool. These diagrams can have a lot of value for even a basic process. SmartDraw makes documenting your process flow easy - even for complicated engineering projects. It is the key document in process design. It includes major and minor flows, control loops and instrumentation. Process Flow Diagram Software. Furthermore, PFDs solidify the interdependence of the organization with external systems. These cookies ensure basic functionalities and security features of the website, anonymously. Read Edit View history. Learn the essentials of process flow diagrams PFD , including the history, benefits and helpful tips with this guide. History Purpose and benefits Process flow diagram symbols and elements How to research and plan the process flow Tips for process flow diagrams How to make process flow diagrams with Lucidchart. A PFD simplifies the process scope and basic information. Crushers: Crushers decrease or adjust the size of materials.

The process flow diagram PFD is a critical component of process design. It is absolutely necessary that chemical engineers know how to read process flow diagrams because it is the primary method of detailing the process and design information.

First, do not worry about the diagram structure. Tips for process flow diagrams These diagrams can have a lot of value for even a basic process. Generally, rather than using numbers, utility streams will be labeled using a certain descriptor. Unleash your team's productivity by combining enterprise-class diagramming, whiteboarding, and data while saving 10x over Visio and Lucidchart! Make a process flow diagram. Process Flow Valves Click to enlarge image Download process-flow-valves. Create powerful visuals to improve your ideas, projects, and processes. Templates Get inspired by browsing examples and templates available in SmartDraw. Zen Flowchart Zen Flowchart is the simplest software to create flowcharts, mind maps, and more. For a smaller, more basic process, you might do this yourself, perhaps even starting with sticky notes. If it is a brand-new process, examine all relevant data and major equipment. A PFD offers several benefits as follows. Next, double-tap to choose the Basic Flowchart option.

0 thoughts on “Pfd process flow diagram”