Print in place

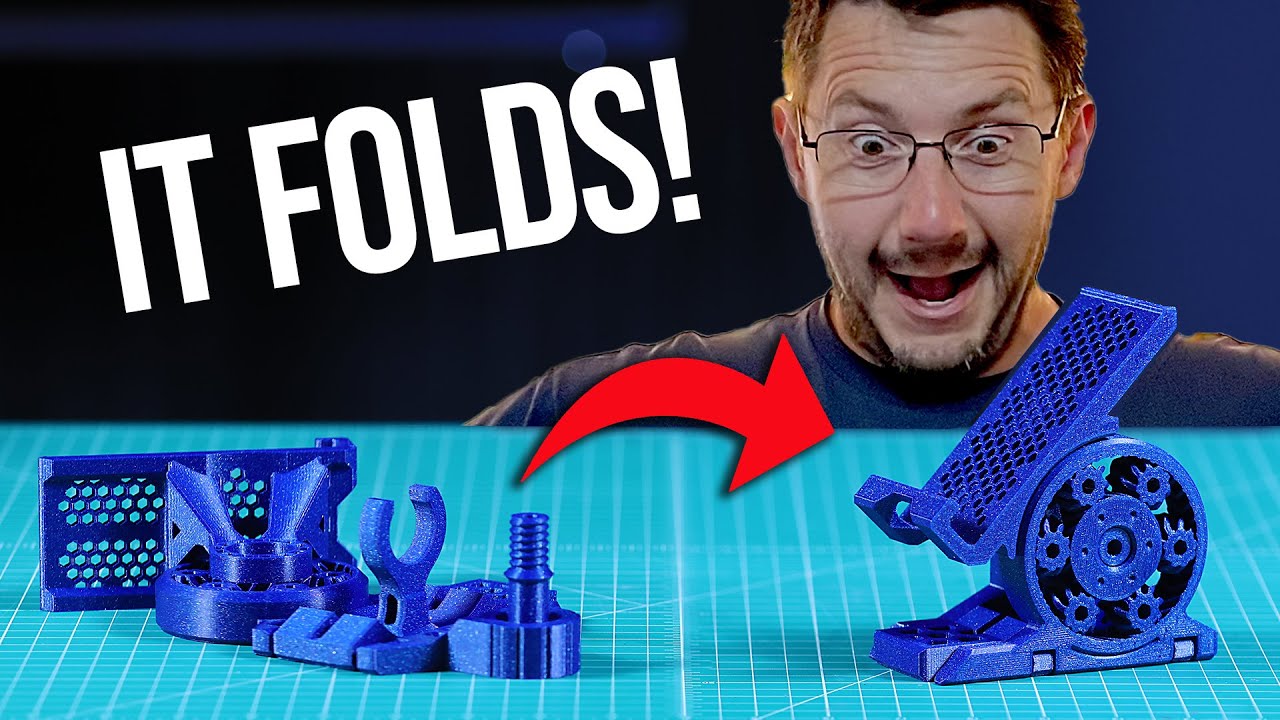

Great trend in 3D printing for several years, "Print-in-Place" or printing in place no support has revolutionized 3D modeling for 3D printing.

Pop Culture. Trending Searches. Trending Tags. Quick Links. Support Creators.

Print in place

By latreides July 20, in Improve your 3D prints. I have been printing for awhile now, and I have never managed to get a "print in place" print to work correctly. What I mean is that any print that has movable parts that are intended to be printed as a single unit, never actually move. The parts are welded to each other. This happens no matter what slicer I use Cura or S3D and no matter what print material or brand I use. Additionally and probably caused by the same issue , any time I print a part that should fit in another part with small tolerances , it never fits. I understand that there is expansion and shrinkage in 3d printing, and the various reasons that the occurs, but clearly other people have managed to get these prints to work just fine. I have not managed with the things I downloaded. Some of the things they say are print in place are not that well made. I use the 0.

Quick Links. Devin Montes is the Creator behind Make Anything, print in place. This 3D printable Flexi Cat is a great example of this, giving you a fast and easy print with moving parts that doesn't have to be put together.

Print-in-place 3D printable models are objects with moveable parts that can be printed as a single piece. There are loads of examples of excellent print-in-place 3D printables around the web. You can find a collection of free print-in-place files below, all of which provide a good starting point for those getting into this type of printing. But before we dive in, let's make sure your printer is configured properly. Print-in-place parts make it easy to create mechanisms with moving parts, but you have to tune your 3D printer settings for the best results.

Tensegrity models, that are popular in 3D printing, can be used both for decorative and functional purposes. Tensegrity, a portmanteau of tension and integrity, describes a system where two or more components are under compression inside a network of continuous tension. It is easy to see that 3d printing would be great for printing the two main parts of a tensegrity table to which wire or string could be added post print, and 3d-print designers have created some beautiful models using this approach. I wanted to take it one step further and design a completely 3D printed print-in-place tensegrity structure. A tensegrity where the strings were single extruded lines of filament printed into, rather than glued or tied onto, the model.

Print in place

By latreides July 20, in Improve your 3D prints. I have been printing for awhile now, and I have never managed to get a "print in place" print to work correctly. What I mean is that any print that has movable parts that are intended to be printed as a single unit, never actually move. The parts are welded to each other. This happens no matter what slicer I use Cura or S3D and no matter what print material or brand I use. Additionally and probably caused by the same issue , any time I print a part that should fit in another part with small tolerances , it never fits. I understand that there is expansion and shrinkage in 3d printing, and the various reasons that the occurs, but clearly other people have managed to get these prints to work just fine. I have not managed with the things I downloaded. Some of the things they say are print in place are not that well made. I use the 0.

Nail bar christchurch

My Models Sign up Log in. Smithy 1, Posted November 26, In any case, it is thanks to this type of beautiful and technical creations that 3D printing will gain its credentials. The few models I have tried, the makerbot robot and the socket wrench from nasa, required that your printer is well adjusted. Categories Categories. Of course, though, like other print-in-place parts, you should avoid scaling this one down. Dustin posted a topic in Firmware , November 28, Adding toys to your desk can improve productivity , along with being loads of fun. And the standard Thingiverse response is "The problem's on your end. What are you trying to print, what size nozzle in use and what size print? How to print in place? You will be surprised to find just how many mechanisms can work when they are printed as a single file. You may have to test the best temperature for the filaments you buy, and print-in-place parts can be a great way to do this. This next design is as smart as it is useful. Go to topic listing.

The model design starts with dimensioning, and I recommend starting with the values shown in the video. In this step, the outside perimeter of the base is defined as a series of lines using the dimensions Width and Depth note that a rectangle was not used in this step since when the outside 4mm corner fillets are added, the rectangle constraints are removed causing the model to fail. The base wall thickness is defined towards the base interior using the Thickness dimension.

Sign up for a new account in our community. Quick Links. Tolerances are crucial when 3D printing print-in-place parts. This print-in-place collapsing katana follows the same concept, only you can print it for yourself at home. I am planning on printing a similar item but 2 colors on UM3 tho i havent decided on what to print more like I am lazy of design at this time? Trending Tags. Gift Box 7. Followers 1. You can find a collection of free print-in-place files below, all of which provide a good starting point for those getting into this type of printing. What are you trying to print, what size nozzle in use and what size print?

0 thoughts on “Print in place”