Ratrig extruder

Hi there, I have been using klipper for over a ratrig extruder now and hardly had any problems, at least nothing I could not solve.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. The new version of the LGX Lite Extruder has a new and improved housing and build allowing for: Improved build quality with a sturdier 2 parts housing design and precise stepper motor centering Tighter tolerances Extra mounting point Increased resistance to heat Micro form factor, featherweight and small footprint Direct replacement for the previous version Enhanced filament grip Includes full size LGX Large Gears and maintenance windows Filament pre-tension lever for repeated results, with 3 presets open; rigid; flexible. It has a new and improved housing, and build quality, with a sturdier 2 parts housing design and precise stepper motor centering allowing for tighter tolerances and enhanced filament grip.

Ratrig extruder

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. The store will not work correctly in the case when cookies are disabled. This is the International Store. My Account Registered Customers. If you have an account, sign in with your email address. Sign In. Forgot Your Password? New Customers.

Problem: Move exceeds maximum extrusion General Discussion. This is an upgrade kit that converts the V-Core 3, ratrig extruder. Single Step Full Guide.

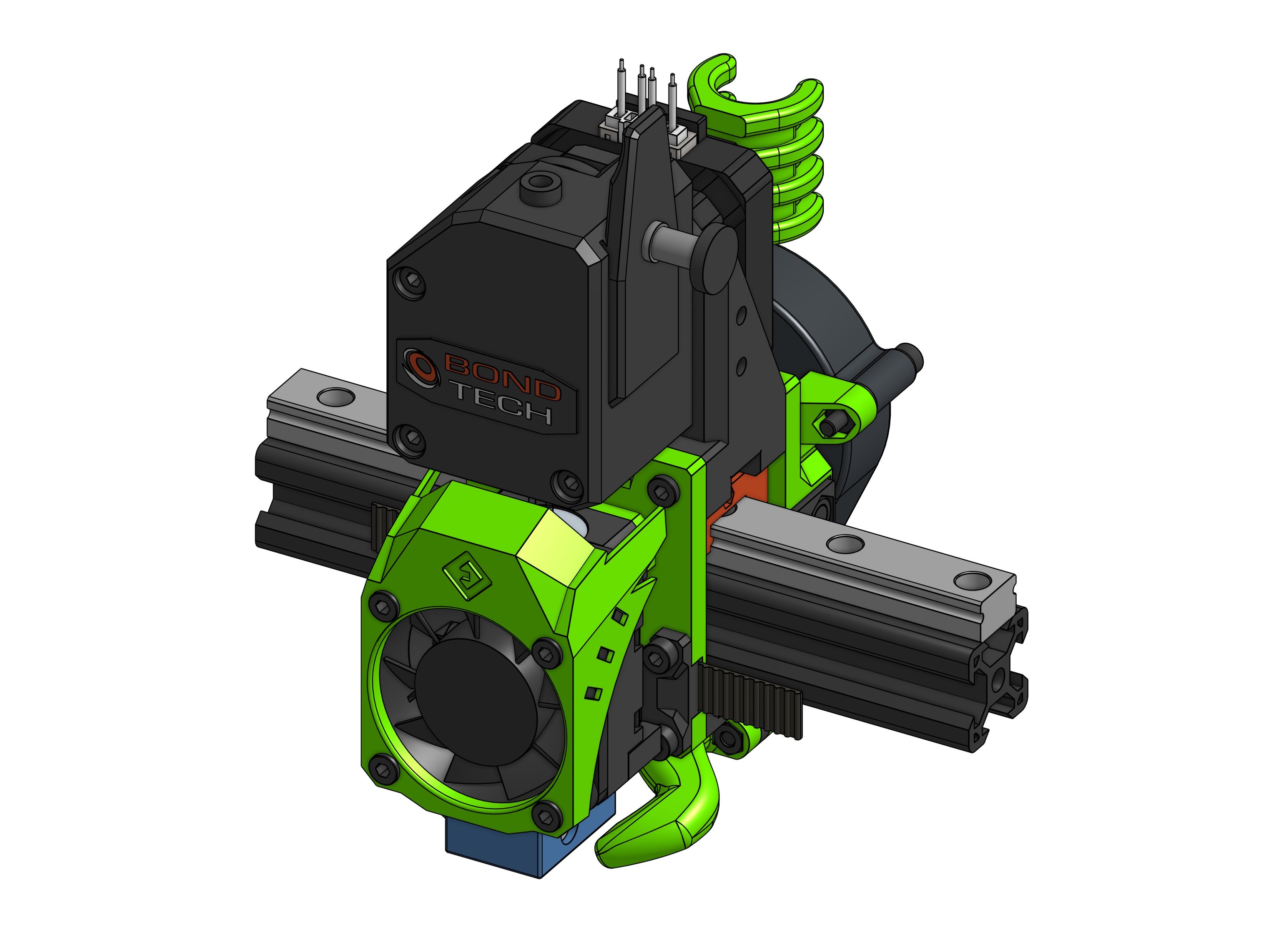

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. You can read more about the new features by going to Bondtech website. Extruder and Stepper Motor go together Preferably, you should always use the extruder attached to the stepper motor when you mount it on a printer. If you need to put a plate in between the stepper motor and the extruder please notice that you need longer screws, and the max supported thickness is 3mm. This image below shows what screws are used on the LGX, and the red ones are used to attach the stepper motor and extruder:.

The new Rat Rig Toolheads are the result of painstaking testing and design iteration to achieve optimal printing performance. With a rigid, light and compact metal body, they use only a few printed parts which are supplied in ABS, to withstand the high temperatures of an enclosed printer. STLs for optional toolboard mounts are also available. This page will guide you throught the easiest upgrade to elevate the performance of the V-Core 3. Below, you will find the CAD, the bill of materials BOM , the repository of printed components featuring all the STL files, and a comprehensive, step-by-step assembly guide. While the EVA 3 toolhead is designed for maximal compatibility with a huge variety of extruders, hot-ends and other accessories, the Rat Rig Toolheads are streamlined to be used specifically with our favourite combination: the Rapido Hotend with the Orbiter extruder. These printed parts are required to upgrade a V-Core 3. They will be available here. The Rat Rig Toolhead V1.

Ratrig extruder

Very easy. Time Required. Suggest a time?? Ready to order? Configure your machine here.

Readers interiors

Sign In. Skip to the end of the images gallery. Forgot Your Password? As I said, I dont know why switching to relative mode fixed the problem, as I never used relative mode in the first place. As far as I understood, this is a safety feature and one should not raise the value. Clear All. I set the slicer to relative mode and that seemed to do the trick, the printer is still running. So here I am looking for a solution. Skip to the beginning of the images gallery. Make sure you keep tensioning until you get rid of all belt slack, and stop tensioning as soon as there's none.

JavaScript seems to be disabled in your browser.

Move exceeds maximum extrusion fault General Discussion. Assemble the belt tensioners with the M5 nuts and pull them in with the M5x45mm screws. Small - px Medium - px Large - px. Align the face and clamp parts over the groove mount of the V6 and fasten them together with M3x25mm screws. The fitting of the PTFE tube is way different from the illustrated example. New Customers. You can read more about the new features by going to Bondtech website. Step 17 Tension the belts. Slide the belts that are in the back of the X gantry into the tension blocks, repeat for 2 blocks. View my Wishlist. My Account Registered Customers. Step 14 Cable holder. Sign In. It always happend when printing the actual object started. Does anyone know if it exists anywhere?

It is a pity, that now I can not express - it is compelled to leave. I will return - I will necessarily express the opinion on this question.

I apologise, but, in my opinion, you are not right.