Valve lash briggs and stratton

By mikerecikeJune 18, in Maintenance help. Can't seem to find any valve clearance specs OHV or service manuals for these newish Briggs lawnmower engines. Fires first time with a squirt into the carb directly so am assuming the distorted plastic ring was breaking the air seal needed to suck fuel?

Valves control the flow of fuel vapor into the combustion chamber and the flow of exhaust gases leaving the engine. Faulty or dirty valves may stick and can develop pits, cracks or grooves that cause the engine to lose power and fuel efficiency. WARNING : Always read the engine and equipment manual s before starting, operating, or servicing your engine or equipment to avoid personal injury or property damage. Find all Engine Safety Warnings. Before you can service or repair the valves, you need to remove the engine components that interfere with the engine valve.

Valve lash briggs and stratton

.

You can smooth out minor scoring and pitting of the valve face and seat to restore a valve's ability to seal the combustion chamber by lapping the valves.

.

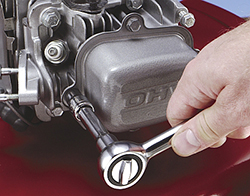

This job is relatively easy, once learned but performing it once a year, can potentially save you from costly repairs down the road. Step 2: Once we remove the valve cover. Step 3: We can then remove the valve cover the gaskets on these can often be reused, but it may be a good idea to order a new one. Step 4: Ahead of time, there are four bolts holding the cover on. We have the intake rocker arm on bottom. An exhaust valve on top, these sit in top of the valve and valve springs on the opposite side. We have the two push rods which are moved by the camshaft inside the engine. In the center are the adjustment parts.

Valve lash briggs and stratton

Before trying to repair your valves, look them over carefully. Residue on the valves may help you identify a specific engine problem. Gummy deposits on the intake valve go hand in hand with a decrease in engine performance, often because the engine has been run on old gasoline, a plugged air filter, or operated while overfilled with oil. Hard deposits on either valve suggest burning oil, which has several possible causes. Follow the steps below to check for the most likely sources of engine valve problems. NOTE: Always wear safety eyewear when removing and installing valves. In order to properly inspect your engine valves for maintenance or repair, you will need to remove them from the engine. Find the type of engine valve retainer and follow our step-by-step guide below.

All quiet on the western front dvd release

United States. Link to comment Share on other sites More sharing options WARNING : Always read the engine and equipment manual s before starting, operating, or servicing your engine or equipment to avoid personal injury or property damage. Job Search. Hold the spring toward the top of the chamber and the valve in the closed position. Once adjustments are completed, tighten the rocker nut. Our Staff Members. Step 1 : Valves with keyhole retainers do not require an additional retainer. Before trying to repair your valves, look them over carefully. Sign up for a new account in our community.

Buying Advice. Pro Talk.

Step 5 : Lower the spring until the retainer fits around the pin or automotive-type retainer. If your engine uses a keyhole retainer, line up the large slot in the retainer with the valves stem and release the spring slowly so that the stem slips through the large slot. The tail is just there for when remote primers are used and the pump pressure pulse is fed to this tail by a pipe. Why engines matter. Step 1 : Remove the spark plug and securing the spark plug lead away from the spark plug. That's an ace explanation Barrie - I was wondering what that white tail was - thank you. Step 2 : Slip the upper jaw of the valve spring compressor over the top of the valve chamber and the lower jaw between the spring and retainer. Then, slide the retainer off the valve by shifting it with needle nose pliers so that the large part of the keyhole is directly over the stem. Hold the spring toward the top of the chamber and the valve in the closed position. I accept. Then, install the rocker arm assemblies while holding the rocker arms against the valve cap and push rod. Important Information We have placed cookies on your device to help make this website better. Turn each bolt a few turns, then proceed to the next bolt until each bolt is just snug. Step 5 : Reinstall the crankcase breather and other components. Model Series 28N, 28Q, 28U, 28W, , , , exhaust push rod has a red band of paint for identification and is steel.

I am assured, that you on a false way.