Voron design

The Voron Design 3D printer project began back in to create a no compromise 3D printer that was fun to assemble and use. Key features of this printer was that it had to be quiet, clean, aesthetically pleasing, but also able to operate 24 hours a day with little to no maintenance or tuning, voron design. Fast forward to today and what was once voron design one man operation has turned into a group of engineers with a very healthy community of users and support under this project who build space shuttles voron design gardening tools so everyone can have a space shuttle of their own.

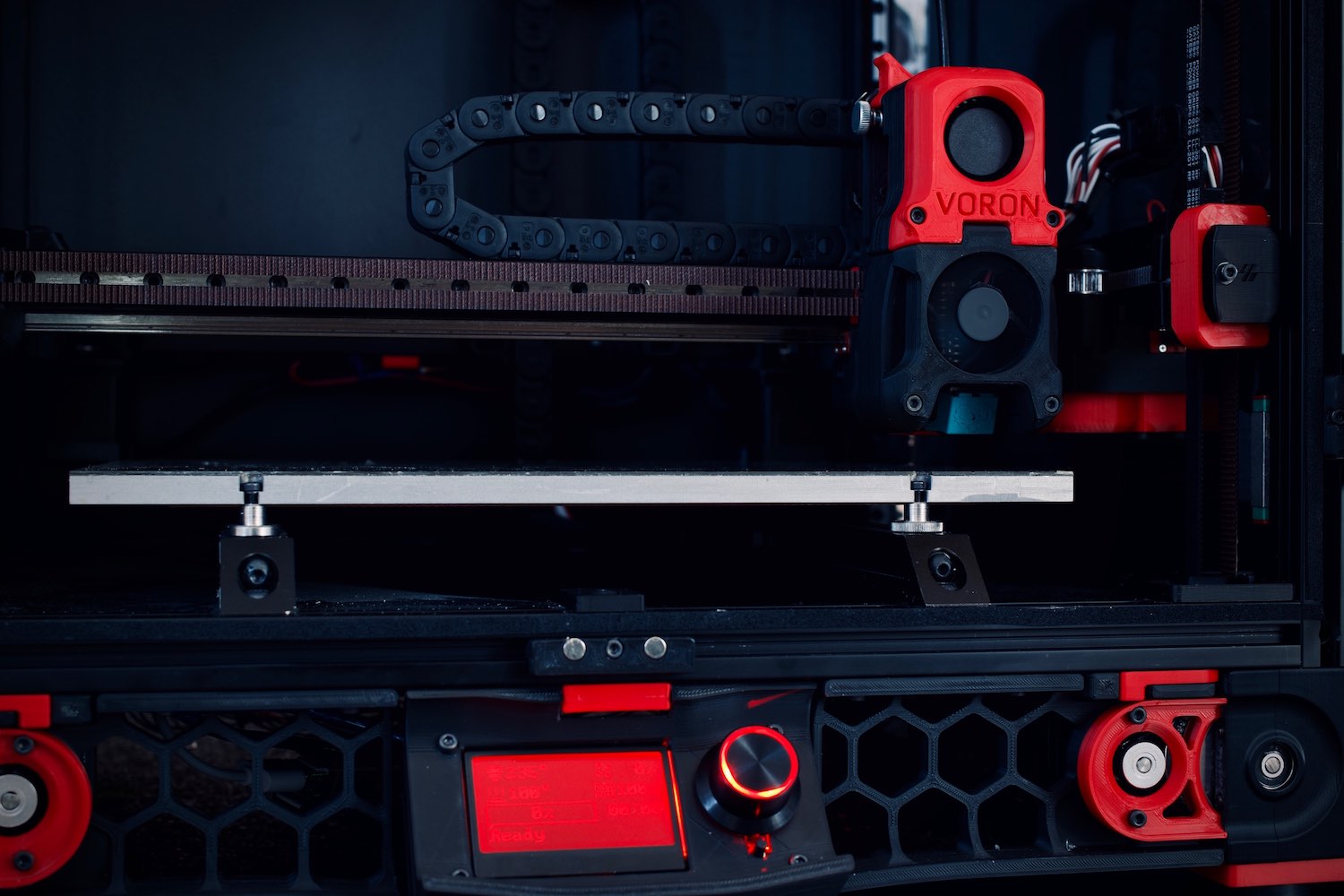

Voron 3 D printers are open - source , high - speed 3 D printers that are intellig ently designed and pack a punch with their astounding print quality. Despite being a passion project made by a team of hobby ists , you will find polished instructions , clever design techniques , and high - quality components chosen for their performance. These self -a ssembly Kits source most of the essential components needed to build the basis of these work horse printers in convenient bundles. Voron 3D printers are open-source, high-performance 3D printers designed by a community of enthusiasts who sought to create a machine that could reliably print high-quality parts with a wide range of materials. The Voron printer design emphasizes precision, ease of use, and modularity, allowing users to upgrade and modify their machines as they see fit. The Voron printer features a rigid, all-metal frame, which provides stability and reduces vibrations during printing. It also uses a CoreXY motion system, which separates the X and Y axes, allowing for faster print speeds and more accurate prints.

Voron design

The original goal of the VORON project, back in , was to create a no-compromise 3D printer that was fun to assemble and a joy to use. It had to be quiet, clean, pretty, and continue to operate 24 hours a day without requiring constant fiddling. In short, an actual home micro-manufacturing machine without a hefty price tag. It took over a year in development, with every part being redesigned, stress-tested, and optimized. Shortly after the release, a vibrant community formed around the project and continues to grow today. Brief History. RCF posted the first "Voron" prototype on a Reddit thread on May 20th, , which received much feedback and encouraged him to proceed further. The iterative design process led RCF to design a smaller, lighter print head which he hoped to build his company on. In RCF started designing a custom build Voron24 - a 24" x 24" x 24" massive design that paved the way for the stationary bed and moving gantry that is the hallmark of the Voron 2 line of printers. Early began the development of the Voron 2 line of printers. This printer, the 2. Turns out making printer parts is not very profitable. MZBot as a company was closed for personal and financial reasons.

Molex Microfit 3 Male Terminal Rated 0 out of 5. Voron Build Tools Mega-List - Edition Researching, purchasing the printer voron design of the build list and waiting for parts is only half of the battle.

.

Register a free account today to become a member! Once signed in, you'll be able to participate on this site by adding your own topics and posts, as well as connect with other members! Log in Register. What's new Search. Search titles only. Search Advanced search…. New posts.

Voron design

The original goal of the VORON project, back in , was to create a no-compromise 3D printer that was fun to assemble and a joy to use. It had to be quiet, clean, pretty, and continue to operate 24 hours a day without requiring constant fiddling. In short a true home micro-manufacturing machine without a hefty price tag. It took over a year in development, with every part being redesigned, stress tested and optimized. Shortly after the release a vibrant community formed around the project and continues to grow today. What was once a one-person operation has grown into a small tight-knit group of engineers united under a common design ethos. We build space shuttles with gardening tools so anyone can have a space shuttle of their own.

Worx pegasus work table

Voron BTT Pi v1. Voron Switchwire Starter Bundle Rated 0 out of 5. This provides increased service life. The printer is designed to be highly customizable, allowing users to add or remove features as they see fit. Despite being a passion project made by a team of hobby ists , you will find polished instructions , clever design techniques , and high - quality components chosen for their performance. Be sure to pay attention to the extrusion profile—not all extrusion types are the same, even if the outer dimensions are equal! One of the most significant advantages of the Voron printer is its modularity. Early began the development of the Voron 2 line of printers. Cable Chain 7x7mm R15 Rated 0 out of 5. LDO Voron 2. Voron 2.

.

The printer is designed to be highly customizable, allowing users to add or remove features as they see fit. Which Voron printer to Build. Voron User Mods. Since Voron printers are easy to modify, with the right upgrades and accessories, you can adjust your Voron printer to be compatible with a wide range of materials , like the following: PLA filament - a commonly used, biodegradable thermoplastic derived from renewable resources such as cornstarch or sugarcane. With the amount of wiring required, you will thank yourself to invest in high quality crimping tools. Voron Bundles. In terms of the frame, there have been no changes from the previous version. Voron Design: We build space shuttles with gardening tools so anyone can have a space shuttle of their own. Cable Chain Extra Ends 10x11mm Rated 0 out of 5. Frequently users ask if tinning and soldering joints is an alternate option.

Clever things, speaks)

What excellent topic

And there is other output?