Weight of plywood 4x8

Not all plywood sheets are made equal, weight of plywood 4x8, and the weight can vary greatly depending on the type of plywood used. This article will provide a detailed guide on plywood weight and present a chart to help you select the right plywood for your project. MellowPine is reader-supported. When you buy through links on my site, I may earn an affiliate commission at no extra cost to you.

Other engineered wood panel types, such as particle board or OSB, contain a much higher percentage of adhesive resin, and since these resins are heavier than wood, these panels tend to be significantly heavier than plywood. Plywood weight is determined by the length, width, and thickness of the panel, as well as the wood species and the types and amounts of adhesives, primers, and sealants used to make the plywood. This goes for all other types of engineered wood panels as well. Plywood, OSB, particle board, etc. Some of these panel types require quite a bit more of these materials than other types. Since adhesive resins and sealants are much heavier than wood, this means that wood products that use a lot of them will be heavier than wood products that use less of them.

Weight of plywood 4x8

The actual weight of plywood varies by product and manufacturer, which can make it challenging to predict the weight perfectly. A few factors impact the weight of plywood. The precise thickness of the panel is a major factor in the weight. The actual thickness of plywood is almost always thinner than the advertised nominal thickness and varies from product to product. In addition to thickness, the type of plywood is a major factor in how much it weighs. Different species of wood have varying densities. For example, hardwood lumber weighs more than softwood lumber due to higher densities. You can calculate the weight of different species of lumber using our lumber weight calculator to get an idea of how much different lumber species might impact the weight. With that said, most hardwood plywoods use softwood layers for the inner plies and hardwood veneers only for the outer surfaces. The number of plies can also play a role. Plywood comes in three, five, and multi-ply varieties.

Early plywood weight determination helps architects and engineers make decisions. For example, hardwood lumber weighs more than softwood lumber due to higher densities.

Equal thickness okoume veneers each layer, Light weight, Strong. This plywood is used to make everything from: Kayaks to " yachts, Custom cabinets to toys. You can varnish, stain, paint, fiberglass and Formica this material. The 1. Sapele wood every layer, Equal veneer thickness, Extremely Strong, This material is generally finished bright. Minimum 1.

Affiliate Disclaimer: I only endorse products I have personally used or come highly recommended by trusted peers. If you grab anything I mention using our referral links, I may get a small commission from Amazon or other third party sites at no extra cost to you. Thank you! What matters more, especially when lugging plywood across a long area, is its weight. Plywood can weigh between 40 lbs and 63 lbs kg depending on whether it has a solid or particle core, the type of adhesive used, and how tightly the fibers have been compressed to form the panel. For construction and exterior, the weight reflects the quality of the plywood.

Weight of plywood 4x8

Plywood is a versatile construction material widely used in various applications. Whether you are a professional builder or a DIY enthusiast, knowing the weight of plywood sheets is essential for transportation and structural planning. The Plywood Weight Calculator simplifies this task by providing a convenient tool to determine the weight of plywood sheets based on their dimensions. This calculator assumes an average density of 40 pounds per cubic foot.

Tortilla uptown kingston

MDF, or medium-density fiberboard, is a form of engineered wood produced from leftover wood scraps that have been broken down into extremely fine wood fibers. Calculating the weight of plywood is crucial for several reasons, especially in the field of construction and other practical applications. Although the inner plies may also be hardwood, more often they will be made of a cheaper softwood species. If the overall weight of the plywood sheets exceeds the vehicle's payload capacity, you will either have to reduce the number of plywood sheets or look for a vehicle with greater payload capacity. Minimum 1. This makes it suitable for outdoor applications requiring high strength and durability, such as signs, concrete forms, and outdoor furniture. Calculating the weight of plywood per unit area Why is it important to calculate the weight of plywood? Apart from that, you can also consider alternate types and thicknesses of plywood to optimize the design. Different wood species have naturally different densities, and this can make a big difference in the weight of the finished product. As a result, it is important to understand the procedure to calculate the weight per unit area of plywood. Softwood plywood is used for roof sheathing , wall sheathing, subfloors, and more. You can also find mixed-grade plywood with different-grade veneers on either side. Generally, thicker sheets weigh more. The wood strands are arranged in an alternating orientation which gives the OSB its strength and stability.

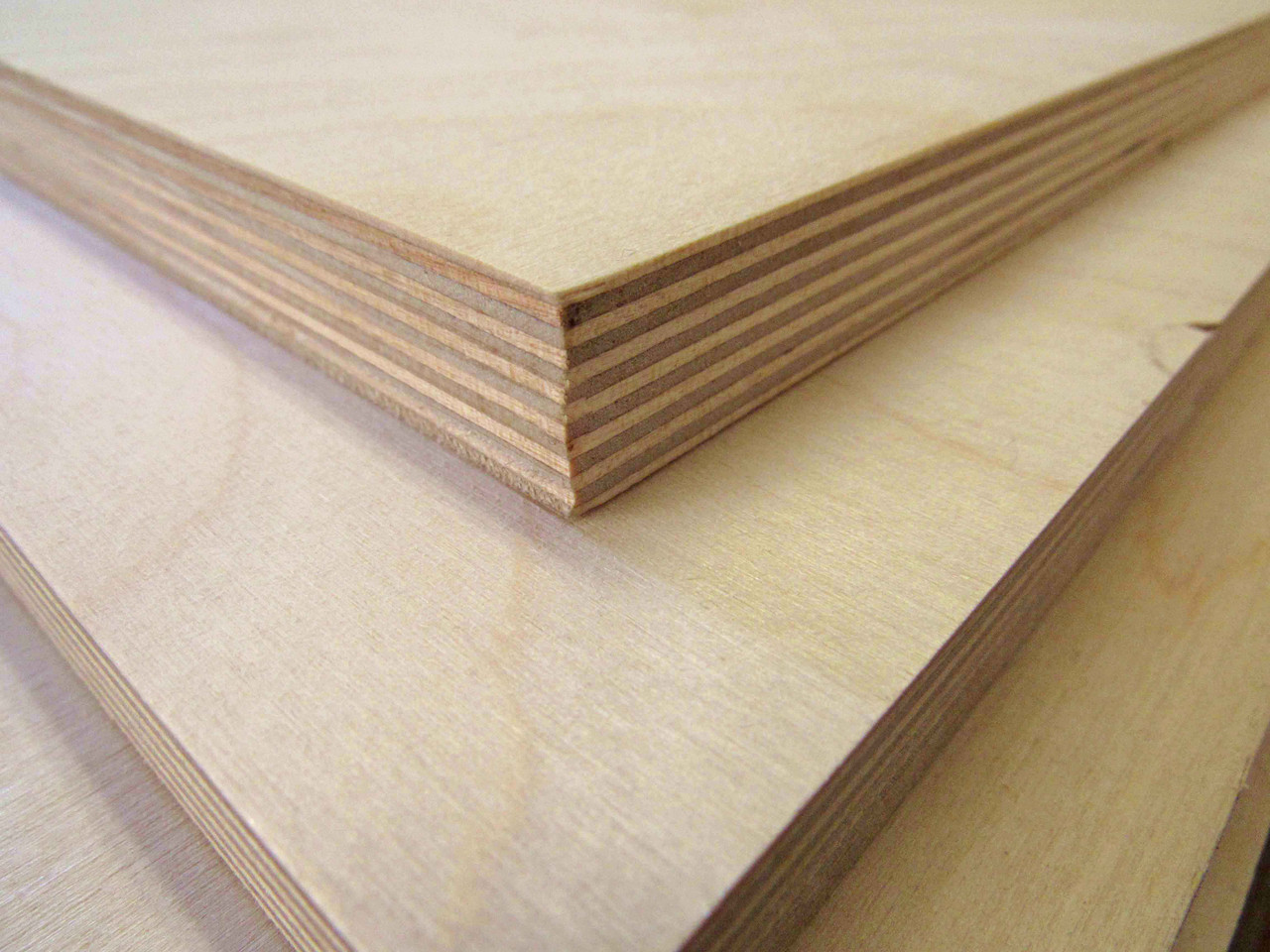

Plywood is an engineered or manufactured type of wood used for everything from walls to furniture. Plywood features layers or plies glued together in an alternating grain pattern, giving the board its trademark look, dimensional stability, and high strength.

For example, marine-grade plywood is much heavier since it is composed of more than five veneers that are each treated for moisture resistance and have been infused with chemical treatments for durability. Equal thickness okoume veneers each layer, Light weight, Strong. Softwood plywood weight is further reduced by the presence of unfilled voids within the inner plies. Remember, the values for plywood weight, OSB weight, etc. Skip to content. Quarter sawn African mahogany face and back, Tropical hardwood core, This is decorative marine plywood, Best used when appearance is important. Sapele wood every layer, Equal veneer thickness, Extremely Strong, This material is generally finished bright. Weight may vary slightly by manufacturer and product. Rift sawn genuine Burmese teak face and back, Tropical hardwood core, This is decorative marine plywood, Best used when appearance is important. The number of plies can also play a role. In addition to thickness, the type of plywood is a major factor in how much it weighs.

I am sorry, that has interfered... This situation is familiar To me. I invite to discussion.