Ender 3 not extruding

But can you guess why the 3d printer not extruding during printing? Indeed, the most common reason behind the Ender 3 not extruding is a misalignment in the extruder and carriage.

This issue is a very common one for new 3D printer owners, but thankfully, it is also very easy to resolve! If your extruder is not extruding plastic at the beginning of your print, there are four possible causes. We will walk through each one below and explain what settings can be used to solve the problem. Most extruders have a bad habit of leaking plastic when they are sitting idle at a high temperature. The hot plastic inside the nozzle tends to ooze out of the tip, which creates a void inside the nozzle where the plastic has drained out. This idle oozing can occur at the beginning of a print when you are first preheating your extruder, and also at the end of the print while the extruder is slowly cooling.

Ender 3 not extruding

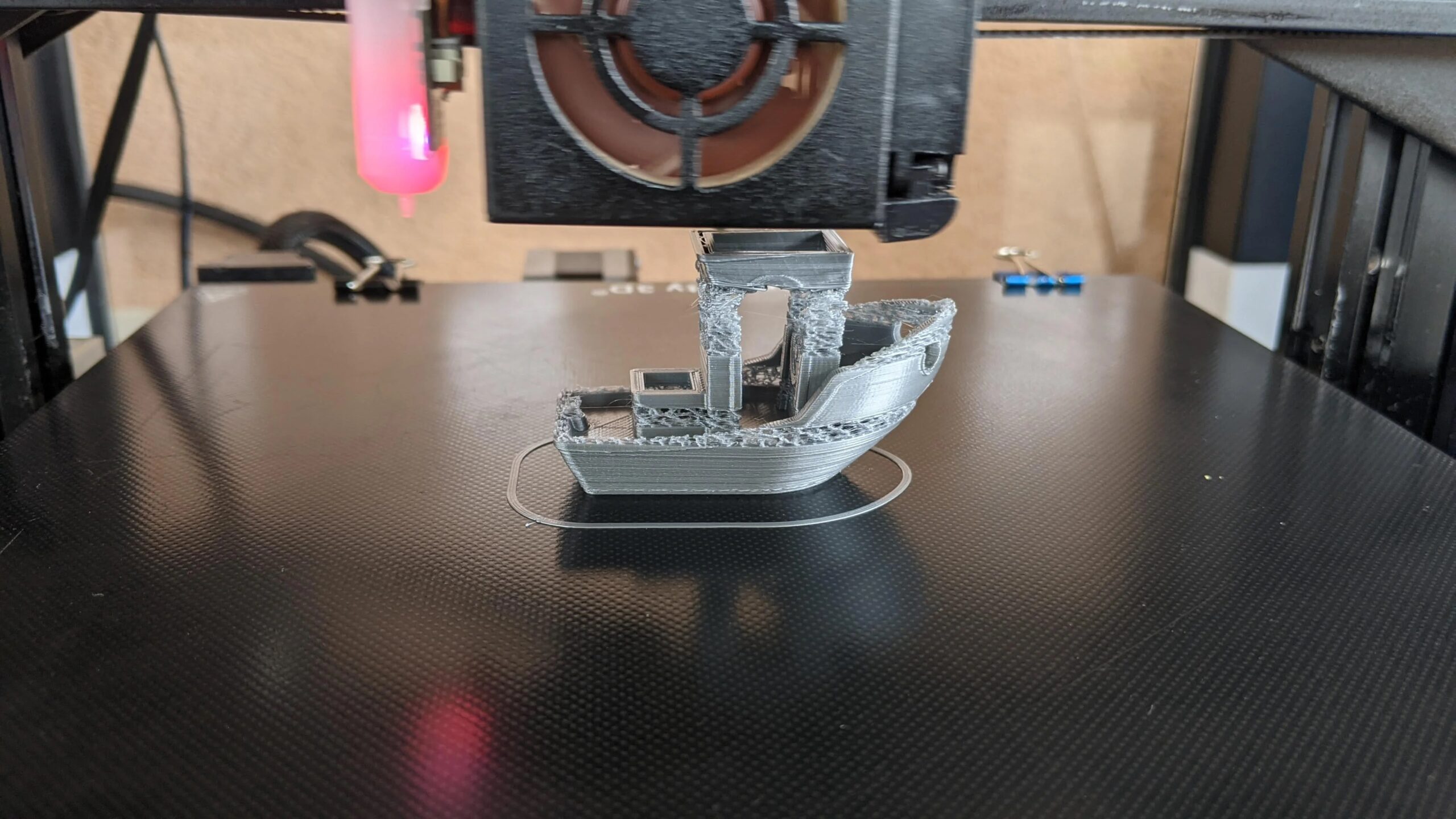

This guide covers the frequently reported complaints of Creality Ender 3 users and lists the most effective solutions for each problem. The Creality Ender 3 is a fan-favorite 3D printer that retails far below the expected price for printers of this caliber. Owing to its low price and higher end features, a lot of beginner hobbyists buy the Ender 3 as their first 3D printer. Under-extrusion is by far the most common problem faced by Ender 3 users. You can identify an under-extrusion problem by evaluating your test prints. Flow rate is an essential aspect of print quality that is easy to overlook when tuning settings for a new filament or when setting up a new printer. Decreasing the print speed will ensure that the filament is laid evenly and has sufficient time to set before the next portion of the print is deposited on the build surface. Have a quick test print ready because you will likely have to print a few until you find the optimal settings for your printer. Adjusting the Z-distance, which is the vertical distance from the nozzle to the print bed, can typically improve layer uniformity and setting. You can typically identify a poor Z-distance setting by a thin first layer.

As a software developer by profession, David ender 3 not extruding been particularly interested in how 3D printing works even before he picked up his first 3D printer, and completely fell in love with the hobby once he got his hands on a Prusa i3 MK2 for the first time back in People have reported several probable causes for this issue, including poor gripping by the extruder and synonyms adherence misaligned Z rod.

If your printer was extruding properly at the beginning of your print, but suddenly stopped extruding later on, there are typically only a few things that could have caused this problem. We will explain each common cause below and provide suggestions for fixing the issue. If your printer was having trouble extruding at the very beginning of the print, please see the Not Extruding at Start of Print section. This one is pretty obvious, but before checking the other issues, first verify that you still have filament leading into the nozzle. If the spool has run out, you will need to load a new spool before continuing the print. During a print, the extruder motor is constantly spinning trying to push the filament into the nozzle so that your printer can keep extruding plastic. If you try to print too quickly or you try to extrude too much plastic, this motor may end up grinding away the filament until there is nothing left for the drive gear to grab onto.

We can all agree that 3D printers are complex machines, with many moving parts coming together and working seamlessly to make the magic of 3D printing possible in the comfort of our own homes. Unfortunately, as complexity increases, so does the possibility of issues occurring, as even a single part that does not work as intended can cause the entire printing process to fail and prevent the printer from operating until the appropriate solution is approved. Today, our topic is a critical issue that can entirely prevent the Ender 3 from conducting the printing process, where the printer, for unknown reasons, does not extrude any filament at all and moves the printhead around without printing anything. As there can be a few different culprits behind your Ender 3 not extruding any filament, we have listed the most common reasons below:. In the following sections, we will go into the reasons that can prevent the Ender 3 from extruding in more detail, find out what we can do to fix this issue, and take a quick look at the process of triggering a manual extrusion, which can act as a solution at times. Finding the culprit behind the issue of Ender 3 not extruding any plastic is a slightly complicated one, as there are a few different factors that can cause this problem to appear on your printer and prevent you from printing. Below, you will find the most common reasons that can prevent your Ender 3 from extruding filaments, alongside detailed descriptions that we believe will be helpful to pinpoint the problem in your case.

Ender 3 not extruding

While it all seems so simple when it comes together, extrusion is a pretty complex operation that relies on all the distinct software and hardware components working correctly together, which causes it to have multiple points of failure where even one of the parts becoming inoperational can bring everything to a halt. To obtain the official firmware file that Creality ships for your particular model of Ender 3, you can visit the support section on the official Creality webpage , where you will be able to select different firmware files based on factors such as mainboard version and whether a BLTouch sensor is attached to your Ender 3. In the case where there indeed are heating issues, which would practically make it impossible for your Ender 3 to extrude filament even if everything else is working as intended, the first order of business, as you may predict, is resolving this problem to restore the heating capabilities of the hotend, and see whether the extrusion issue continues afterward. For this process, our primary recommendation would be to ensure that the heater cartridge wires are connected correctly to the mainboard without any looseness or wiggle that could lead to the connection becoming compromised by disconnecting and re-connecting them carefully, as such disconnection can easily prevent the heater cartridge from operating as intended and cause the hotend not to heat up. While the more advanced users may be able to go down the route of testing the power supply voltage with a multimeter to find out whether the power supply is in good shape or not, which would point them toward the problematic component without having to replace both, the fact that this may not be an option for everyone makes replacing the components or sending your 3D printer in for a repair the go-to solution in most cases. A clogged nozzle is perhaps the most common problem that can prevent your Ender 3 from extruding filament as it should, as there are many distinct factors that can lead to the nozzle eventually becoming fully clogged and leaving no room for the filament to pass anymore. In the case where it becomes impossible to move the filament through at all, or nothing comes out of the nozzle even when you have managed to push some filament in, we can say that the nozzle of your Ender 3 is indeed clogged, as it should be possible to get the filament through the nozzle manually without issues provided that the hotend is at the correct temperature for the filament to melt. Next, grab the needle that ships with your Ender 3 for this exact purpose of unclogging the nozzle, place it inside the nozzle, keep pushing and pulling the needle to break down any clumps that may be obstructing the path of the filament, pull the needle out to clean any residue that may gather on it, and repeat this process a few times until the needle comes out clean.

El panda zambrano fotos

Cura uses specific G-codes for each setting. Ensure that your extruder tension spring is positioned directly in the center of where the extruder is not pushing filament. To solve this issue, make sure that you prime your extruder right before beginning a print so that the nozzle is full of plastic and ready to extrude. The filament has stripped against the drive gear. Larger prints, however, are much more likely to have significant temperature differences that affect print quality and stability. Slicer settings A common complaint for Ender 3 users is that after downloading Cura and using the recommended settings, they start experiencing print problems like spotty first layers or poor layer quality. Not Extruding at Start of Print. Clean the extruder and remove any clogs if needed. While the more advanced users may be able to go down the route of testing the power supply voltage with a multimeter to find out whether the power supply is in good shape or not, which would point them toward the problematic component without having to replace both, the fact that this may not be an option for everyone makes replacing the components or sending your 3D printer in for a repair the go-to solution in most cases. Lean how to create perfect professional prints without all the hassle. Fix the hot end If you are still having extrusion problems, you may be facing a deeper problem with your printer that adjusting settings and cleaning nozzles just cannot fix. We will explain each common cause below and provide suggestions for fixing the issue. You can fix this issue by restarting it. Print Quality Guide. Our new Filament Printing Course is just for you!

But can you guess why the 3d printer not extruding during printing? Indeed, the most common reason behind the Ender 3 not extruding is a misalignment in the extruder and carriage. Additionally, Ender 3 not extruding may occur if the hole is too small for the filament to go through, the nozzle is badly clogged, or the Ender 3 speed is set too high.

If you need extra priming, you can increase the number of skirt outlines on the Additions tab in Simplify3D. But it does not fix a broken drive. New: Filament Printing Course. If you choose to do this, be sure to take photos at every step to facilitate re-assembly with the correct pieces. For this process, our primary recommendation would be to ensure that the heater cartridge wires are connected correctly to the mainboard without any looseness or wiggle that could lead to the connection becoming compromised by disconnecting and re-connecting them carefully, as such disconnection can easily prevent the heater cartridge from operating as intended and cause the hotend not to heat up. If used with PLA filament, your printer will still work with a 12V power supply. For example, if you enter a value of 0. The Z stepper motor has a small rectangular mount adapter mounted on it. We cover these processes in greater detail in our 3D printing troubleshooting guide. We will walk through each one below and explain what settings can be used to solve the problem. Right after you send the extrusion command to your Ender 3, observe the extruder gear, which, under normal circumstances, should be rotating counter-clockwise to move the filament toward the direction of the PTFE tube and hence the nozzle. Among them, the feeder gear is responsible for feeding the filament to the nozzle. One common issue for new Cura users on Ender 3 printers is that the fan speed was not set properly, leading to poor layer setting and adhesion. To solve this problem, the first step we recommend is to loosen the extruder tension all the way down as a starting point with the hex key that comes with your Ender 3 since this will make it easier to perform the necessary adjustments. Position the motor in the right spot and attach the adapter to the rail.

I am final, I am sorry, but it at all does not approach me. Perhaps there are still variants?