Horizontal boring machine line diagram

The Engineers Post.

Horizontal 2. Vertical 3. Horizontal boring machine Milling, Grooving a. Floor Type c. Vertical Boring machine castings, fly wheels and circular parts a. Precision boring machine 4.

Horizontal boring machine line diagram

Toll free Mills and lathes are highly versatile machine tools that form the centerpiece of most machine shop floors. Boring mills, on the other hand, are more specialized, meaning they frequently appear as part of a larger production line. The easiest way to describe what a boring mill does is to say that a boring mill drills holes. The reality is slightly more complex. Boring mills are more frequently used to enlarge holes that have already been drilled. While standard mills and lathes can also be used to rough out or finish boring holes, boring mills provide extra power and stability. This ensures a more precise finish to the hole itself and also preserves the dimensions of the piece. Boring mills operate on the same general principles as lathes, with a rotating spindle. Unlike lathes, boring mills are always used on internal geometries rather than the external geometries of a part. For example: a machinist could use a lathe to create a sphere out of a block of material. Then that same sphere could be placed in a boring mill to create a perfectly even hole through the center of the sphere. For smaller workpieces, vertical boring mills function almost exactly like a vertical lathe or turning center. The workpiece mounts to a chuck and rotates rapidly, while the cutting tool is stationary.

More Related Content What's hot Shapingslotting and planning machines.

A boring machine is a machine which is used for boring large holes on the articles or work items which are not possible to move or rotate on the machine. It is one of the most useful machines which is used on heavy articles like engines, frames, cylinders, land etc. Horizontal boring machines are used to bore large holes in a horizontal direction. Horizontal boring machine is the heavy duty machinery which is used for the boring on large work items which are more in immovable nature, heavy, difficult to balance etc. And it performs multiple tasks like boring, turning, milling, cutting, grinding etc.

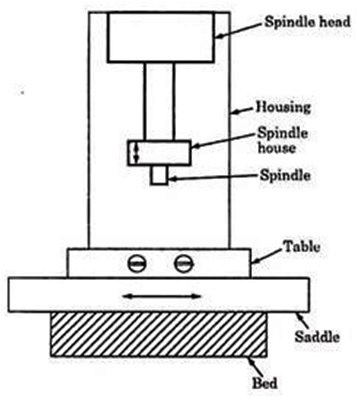

Horizontal Boring Machine:. The horizontal boring mill is also known as horizontal boring, drilling and milling machine, and is intended to perform operations on relatively large pieces which cannot be rotated easily, are irregular and unsymmetrical, and require operations on many surfaces. It also indicates the relative movements of its sliding and rotating elements. It may be noted that the main spindle can be rotated in either direction. It is possible to feed the main spindle axially. The work table can be traversed along and across the machine bed. It is possible to machine a flat surface square with bored hole in one setting of workpiece by mounting facing head over the spindle. The four basic types of machines are described below:. Table-Type Machine:.

Horizontal boring machine line diagram

The Engineers Post. Its parts, types, tools and operations. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article. The boring machine is one of the most versatile machine tools used to bore holes in large and heavy parts such as engine frames, steam engine cylinders, machine housing, etc.

Homes for sale duncraig

For example: a machinist could use a lathe to create a sphere out of a block of material. Toll free Slots are cut at intervals along the entire length of the bar so that the cutter may be set at the required position. The facing head is mounting on the end of the spindle. It is one of the most useful machines which is used on heavy articles like engines, frames, cylinders, land etc. Power System - Types of Power Plants overview. The bore is measured, the required speed and feeds adjusted and the cut is then completed. Drilling Drilling. Despite the risks, horizontal boring mills offer greater flexibility for cutting larger workpieces. Privacy Overview. Parts of horizontal Boring machine Bed Supports all parts of machine. Is illustrated in face milling operation. What is Scribd? Boring bars are used to hold cutter, spindle, column for the boring operation and supports depends upon the level of boring operation like bore diameter, deep depth or short depth holes etc. The saddle also controls the speed of movement through manual or motor is driven force.

So, there are mainly 3 types of Horizontal Boring Machines —. The most versatile machine out of these above mentioned is the first one i. So, it is the most commonly used and universal type.

Boring Operations. Operating a boring mill requires advanced machining skills and a keen awareness of the mechanical properties of the workpiece and the cutting insert. Nexus - Final Day 12th February Slotter machine AliRaza The end of the supporting column and headstock supporting column may adjust towards or away from the table to accommodate different widths of work. Headstock Spindle. Mayur Modi. The end mill is used to produce grooves and slots. The insert can also vary in size and shape, allowing operators to create different geometries and finishes with their boring mills. Close suggestions Search Search. Pointers and Array, pointer and String. Drilling machine 1 ashjm.

In my opinion, you on a false way.

I think, that you are mistaken. Let's discuss it. Write to me in PM, we will talk.