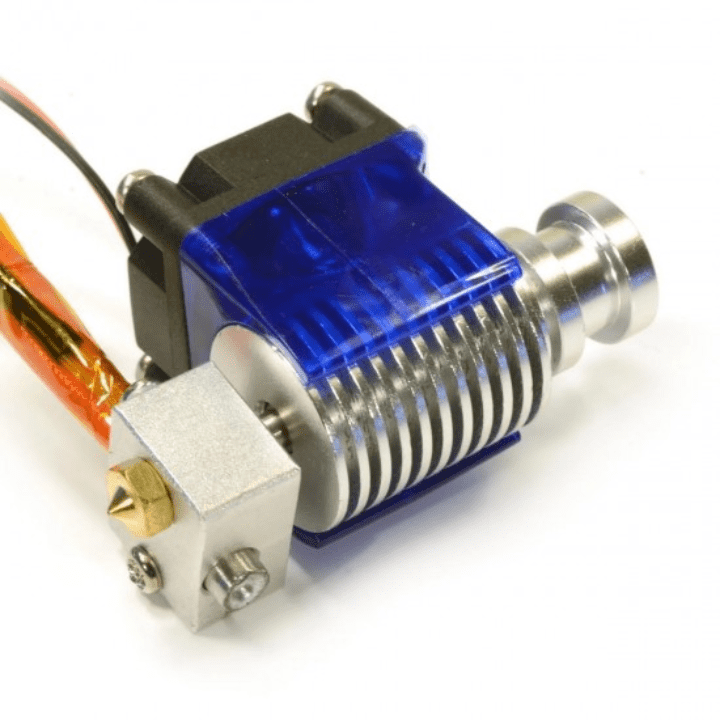

J head hotend extruder

The hotend kit of a 3d printer is an important component of a 3d printer.

Lost password? Recover password. Remembered your password? Back to login. Nozzle Size: 0. All the products can be returned within 14 days from the date received.

J head hotend extruder

This nozzle is a combination of ideas from other nozzle designs combined with a goal to reduce the number of custom machined parts to a bare minimum. By reducing the number of machined parts, it is hoped that the cost of this hot-end can be kept down while improving the reliability. By not having the filament in contact with this joint it is hoped that any possibility of leakage will be completely eliminated. However, instead of the heater resistor being mounted parallel to the path of the filament it is mounted perpendicular to the path of the filament. This was done to both reduce the length of the nozzle and to make it a little easier to run the leads from the heater resistor. Combining the heater and nozzle also helped to meet the goal to keep the number of custom machined parts to a minimum. Summary: Added a heat sink in order to print PLA. To reduce weight, an aluminum nozzle is used. Summary: Removed the heat sink and added a series of vents to provide cooling. Summary: Reduced the size and increased the length of the melt zone. Summary: Uses a heater cartridge and two thermistors. If the firmware Marlin is properly configured, and the thermistors are not reporting the same temperature, the firmware will turn off the heater cartridge.

The most reliable version has modifications to the groove closest to the brass nozzle. If the firmware Marlin is properly configured, and the thermistors are not reporting the same temperature, the firmware will turn off the heater cartridge, j head hotend extruder. Use a brim or raft when printing objects with a small footprint to improve adhesion to the print bed.

Want to improve the quality and accuracy of your 3D prints? Our calculators can help you optimize your 3D printer's settings and achieve the best results possible. The Pocket Shroud attaches with existing hardware right on the front of your hotend fan to give you Dual radial layer cooling fans! Buy Now Datasheet. Specifications: Weight: 30g Height: 54mm Filament Diameter: 1.

This nozzle is a combination of ideas from other nozzle designs combined with a goal to reduce the number of custom machined parts to a bare minimum. By reducing the number of machined parts, it is hoped that the cost of this hot-end can be kept down while improving the reliability. By not having the filament in contact with this joint it is hoped that any possibility of leakage will be completely eliminated. However, instead of the heater resistor being mounted parallel to the path of the filament it is mounted perpendicular to the path of the filament. This was done to both reduce the length of the nozzle and to make it a little easier to run the leads from the heater resistor. Combining the heater and nozzle also helped to meet the goal to keep the number of custom machined parts to a minimum. Summary: Added a heat sink in order to print PLA. To reduce weight, an aluminum nozzle is used.

J head hotend extruder

Want to improve the quality and accuracy of your 3D prints? Our calculators can help you optimize your 3D printer's settings and achieve the best results possible. The Pocket Shroud attaches with existing hardware right on the front of your hotend fan to give you Dual radial layer cooling fans! Buy Now Datasheet. Specifications: Weight: 30g Height: 54mm Filament Diameter: 1.

Francine smith porn

Your email. In this groove, the supports are not drilled out and the groove is milled to 0. To be eligible for an exchange, your item s must be unused and in the same condition as received with the original packaging. The machining process can vary depending upon available machinery and tooling. Summary: Added a heat sink in order to print PLA. A test print using PLA. Early SAE Blueprint. Shipping From: China China. Check out the 3D printer calculators page! Refunds through credit cards are time-sensitive, depending on the credit card issuer's policies. Over time, slight improvements were added to this nozzle holder. Refund Policy. Use a layer cooling fan to help the plastic solidify faster and reduce the risk of warping or other defects. Add to cart.

This kit contains the old thermistor, heater block, sleeving, cooling fan with holder. Building on their signature high temperature performance that allows you to print high temperature materials 3D has now focussed on adding increased functionality with soft and flexible filaments.

Imported pure transparent PTFE tube is used, and the feed is visible. July 25, Nozzle Size: 0. By not having the filament in contact with this joint it is hoped that any possibility of leakage will be completely eliminated. If the firmware Marlin is properly configured, and the thermistors are not reporting the same temperature, the firmware will turn off the heater cartridge. Summary: Removed the heat sink and added a series of vents to provide cooling. During the enrichment printing process, the X and Y directions are controlled by the nozzle movement and the Z direction, i. If you need 0. Tips: Calibrate your 3D printer regularly to ensure that the extruder is applying the right amount of pressure and that the print bed is level. Type: Direct Hotend Direct Hotend. However, the taper would not have to be too precise as PTFE is quite flexible. I've been using J-head hot-ends for 10 years. The Pocket Shroud attaches with existing hardware right on the front of your hotend fan to give you Dual radial layer cooling fans!

0 thoughts on “J head hotend extruder”