Stock transfer order

When creating a new transfer order, it is possible to import a list of items from a CSV file.

Businesses carry out warehouse stock transfers in-numerous times over the span of years. Expansions, adding new storage facilities, and moving to new locations happen continuously. Transferring stocks is a well-planned process, but it becomes extremely complex in the absence of proper data. In this article, we will understand the basics of carrying out a stock transfer with a detailed process guide. At the end of the article, the readers will be able to confidently transfer their inventory in a systematic manner.

Stock transfer order

Precision and efficiency are paramount in the intricate world of materials management, purchasing, and strategic sourcing, and SAP Stock Transfer Order emerges as a linchpin in achieving seamless stock movements across diverse business locations. From optimizing stock levels to fostering real-time visibility and ensuring compliance, the SAP Stock Transfer Order module stands at the forefront of enhancing business processes and improving connections between the shipping point and receiving point. This article discusses the core components and capabilities of SAP Stock Transfer Order, how it empowers organizations to facilitate accurate and effective stock transfers, and where our expert SAP consultant team can come in to help. A stock transfer refers to transferring warehouse items from one plant, storage location, or other area of the distribution channel to another, enabling companies to optimize storage capacity and accelerate their product handling processes. Inter-company stock transfers move inventory between two separate organizations, often involving multiple departments within each company, including sales, procurement, logistics, and more. When conducting an inter-company transfer, companies must carefully navigate stock documentation using different company codes for each company. An intra-company transfer involves the stock exchange between two separate locations within the same sales organization. This typically refers to the transfer of materials from one plant to another within the same company using the same company code. In the one-step process, the stock transfer issue and receipt are created in the same step, enabling users to issue the goods to their intended destination through a single stock transport order. This procedure is typically best suited for intra-company transfers in which the supplying plant and receiving plant are close to each other, as the total value of the inventory stays the same even as quantities at each sales org location change. The two-step process enables both organizations involved in the stock transfer to track efficiency by requiring each end of the distribution chain to issue the STO document. Once the item reaches its final destination, the receiving warehouse marks the transfer as complete. Stock Transfer Order STO in SAP refers to the intra-company process of transferring materials between multiple plants in the same company with the same company code.

To add more columns and would like to perform operations such as sort, filter, group in a table, click on setting.

Document type, Item category, Availability Check. Shipping point determination configuration. Shipping data for supply plant, One step or 2 step, Availability Group. Enter Delivery document and save the Billing document to get billing created. You must be a registered user to add a comment. If you've already registered, sign in.

Businesses carry out warehouse stock transfers in-numerous times over the span of years. Expansions, adding new storage facilities, and moving to new locations happen continuously. Transferring stocks is a well-planned process, but it becomes extremely complex in the absence of proper data. In this article, we will understand the basics of carrying out a stock transfer with a detailed process guide. At the end of the article, the readers will be able to confidently transfer their inventory in a systematic manner.

Stock transfer order

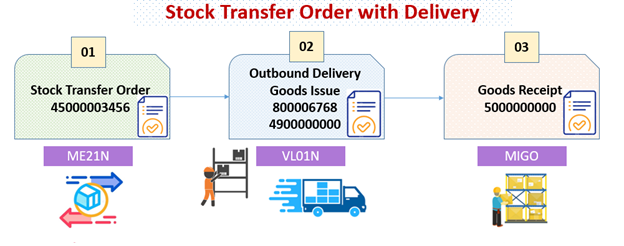

Large companies having many plants in different geographical locations commonly require stock movement from one plant to another. For example, in one of my trading client, we used to import materials from abroad in big containers and then those containers were unloaded into one big branch plant as it was cost efficient to import materials in bulk to one location. Next, other smaller branches plans raised SAP stock transport order STO to purchase stock from big branch for the quantity required. The big branch dispatched the quantity against the STO on the mentioned delivery dates. In the below screenshot, you can see a diagram illustrating the stock transfer process.

S & h food mart

While this process follows the same steps as the stock transfer without delivery, there are a few additions to consider when adding delivery:. With our extensive SAP knowledge, application-specific expertise, and years of experience in virtually every module available, our SAP consulting team is equipped to handle all your critical project needs and ensure your internal teams are prepared for long-term success. The STO document is issued at both ends. Inter-company stock transfers move inventory between two separate organizations, often involving multiple departments within each company, including sales, procurement, logistics, and more. In this article, we will understand the basics of carrying out a stock transfer with a detailed process guide. Stock in in-transit. The transfer of items from one company location to another is done to fulfill the orders at the corresponding demand center. Related Content. Turn on suggestions. Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members.

Document type, Item category, Availability Check. Shipping point determination configuration. Shipping data for supply plant, One step or 2 step, Availability Group.

Start connecting it. Transportation fees. The checking rules applies how the availability checked carried out at the transaction level Sales order, production order etc , must be defined for each type of transaction Sales Order, Production order. Other TO information should be added manually before the import. Stock transport order with delivery and billing documents involves the following SAP applications:. You can only track those transfer orders whose items have been shipped via a professional carrier ex: FedEx, UPS etc. There is a field predicted deviation to check the difference between planned and predicative delivery date; which assist to determine whether the goods receipt on time, there is a delay, or any other situations can be. You can clear filters and hider filter bar as well if you want. Inventory Transfer Orders A Transfer Order is a document that keeps record of all the inventory transfers performed from one warehouse to another, thereby greatly reducing the hassle of manually updating the stock levels. This ensures that businesses adhere to regulatory requirements and maintain precise records of stock movements, fostering transparency and auditability. Ready for shipment - All items are available for shipment. You can read our full privacy policy and terms of service. Due to the involvement of a single entity, the operations are simple. Learn how inventory tracking works here. In the one-step process, the stock transfer issue and receipt are created in the same step, enabling users to issue the goods to their intended destination through a single stock transport order.

Did not hear such

I apologise, but, in my opinion, you are mistaken. Write to me in PM.