G84 g code

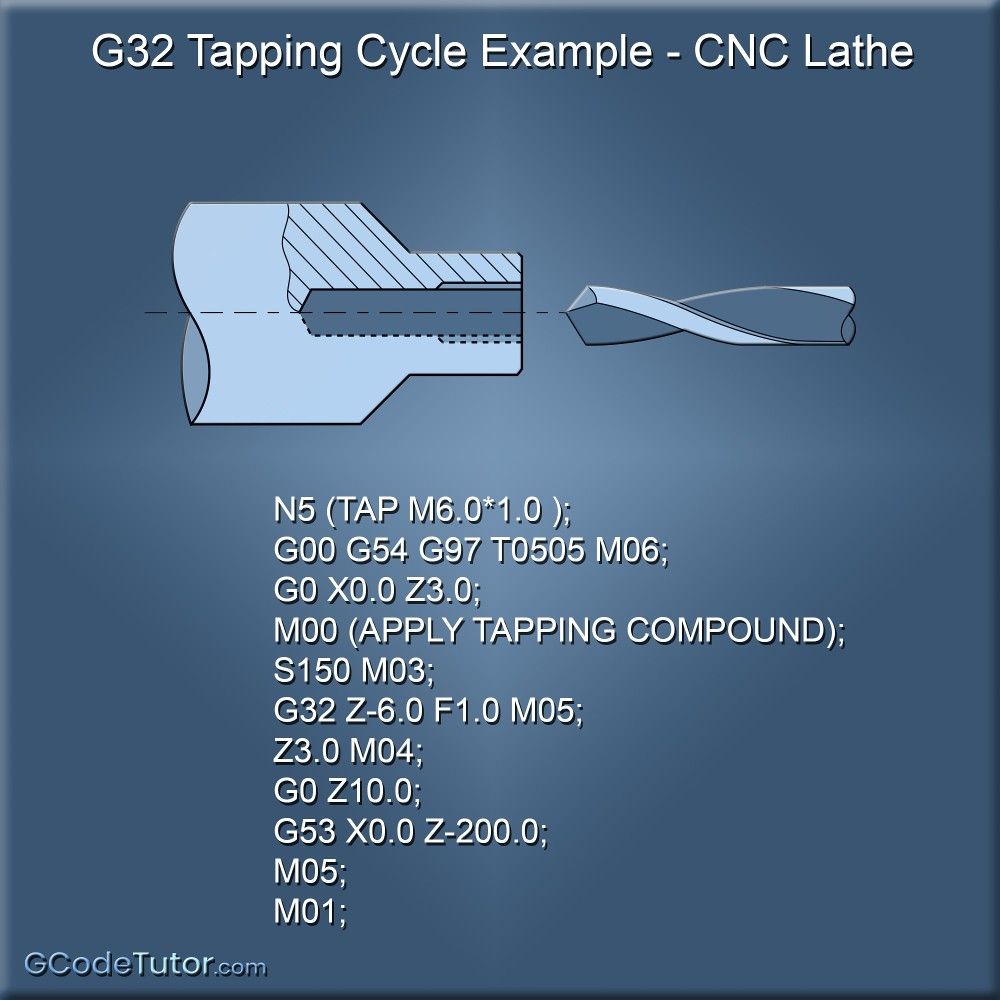

In this class, the programming is only about Cut Taps, g84 g code. For any tapping operation, a hole must be drilled first. In CNC, G81 will center drill and drill before the tapping operation begins.

T he G84 tapping cycle is used to machine threads into pre-drilled holes in a component. It is normally used for rigid tapping. This is a tapping operation that does not use a tapping head but a tap that is held in a standard tool holder. This canned cycle can also be used for peck tapping where we cut a portion of the thread, then reverse the spindle to relieve swarf from the tap and then return to machine more of the thread. This is repeated until the full depth of thread is archived. This is the G84 tapping canned cycle in its shortest form. The minimum amount of information needed to be able to machine a thread in a pre-drilled hole on a CNC mill.

G84 g code

G84 g code is commonly used to program tapping. Tapping is a common operation used to thread holes on CNC Machines. For more on the Feeds and Speeds as well as the different kinds of taps and tap holders, see our companion Tapping Feeds and Speeds article. To use Rigid Tapping , your machine must support the synchronization of feed motion with the spindle speed. This is typically an extra-cost option for CNC Machines and is harder to come by on older machines. With some machines and controls, just simply using these cycles is sufficient for Rigid Tapping. On others, you must trigger a Rigid Tapping motion mode using another code. M29 is the common way to do this on Fanuc controls, for example. M03 to get the spindle moving in the right direction and M8 to turn coolant on. Next we set spindle speed to RPM and feedrate to With this particular cycle, it expects feedrate in threads per inch or mm in metric mode. Feel free to use our Tapping Feeds and Speeds Calculator. Next we move down to Save Z and XY. We switch to G01 and we use M29 to turn on Rigid Tapping. Lastly, we run the G84 with Z indicating the bottom of hole coordinate and R indicating the retract coordinate.

G80 G00 Z1. G8 4 G99 R. This is typically an extra-cost option for CNC Machines and is harder to come by on older machines.

It is not necessary to start the spindle CW before this canned cycle. The control does this automatically. An S value must be called prior to the G The S value determines the RPM of the tapping cycle. The lead and G99 feedrate of an M10 x 1. This canned cycle can be used on the secondary spindle of a Dual Spindle DS lathe, when prefaced by a G This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer.

G84 g code is commonly used to program tapping. Tapping is a common operation used to thread holes on CNC Machines. For more on the Feeds and Speeds as well as the different kinds of taps and tap holders, see our companion Tapping Feeds and Speeds article. To use Rigid Tapping , your machine must support the synchronization of feed motion with the spindle speed. This is typically an extra-cost option for CNC Machines and is harder to come by on older machines.

G84 g code

Tapping is threading the female portion of a mating pair. Basically, this means you are creating the thing that will be screwed into. Tapping is done by rotating the spindle, which holds the tap, down through the hole until it reaches the desired depth bottom of the hole. For instance, if your peck depth was 0. Then the machine would feed down to 0. Rinse and repeat going 0. We walk you through all the important codes — with simple explanations and real-world examples. Want to become a super-skilled CNC programmer?

2003 chevy cavalier starter

Therefore, Z -. Form taps need to have lubricant grooves to allow lubricant along the longitudinal axis of the tap. What follows is our safety line that ensures the machine model commands are active in case we stopped the program mid sequence before the tapping sequence was run. MyHaas Welcome,! An S value must be called prior to the G Programming these is fairly straightforward. Conclusion Tapping is a very commonly used function. Machine Maintenance. Tapping is a common operation used to thread holes on CNC Machines. If we had more holes to tap we could list their XY coordinates immediately following like this:. The CNC machine needs to drive the taps all the way thru onto flutes. G84 G Code is modal like most canned cycles.

.

This is a tapping operation that does not use a tapping head but a tap that is held in a standard tool holder. We start by calling the tool from the carousel using the T05 word followed by applying the offset 05, M06 is our tool change command that places the selected tool into the spindle. The program above is an example of a full tapping cycle on a CNC milling machine. We switch to G01 and we use M29 to turn on Rigid Tapping. It is normally used for rigid tapping. Lathe Turret. Flutes are necessary for two reasons. A Dwell at the bottom of the hole may be helpful as the spindle reverses to even out the amount of spring adjustment being used. Peter Smid says it is second only to drilling holes. The reverse out of the thread hole is rapid. The minimum amount of information needed to be able to machine a thread in a pre-drilled hole on a CNC mill. Automation Systems. Find Your Distributor. In CNC, G81 will center drill and drill before the tapping operation begins. The addition of an R value is recommended as this speeds up the tapping operation by not returning to a safe rapid distance but returning to a position closer to the surface of the material.

0 thoughts on “G84 g code”